Laser Diffraction Particle Size Analysis (PSA)

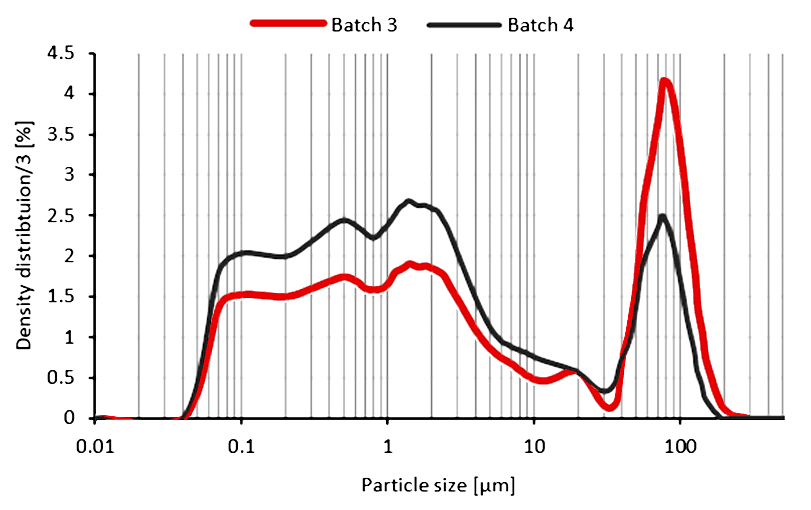

Laser Diffraction particle size analysis (PSA) is an indirect, optical technique that measures particle size distributions – by equivalent spherical diameter (D10, D50, D90) – in liquid and solid samples.

Strengths

- Particle size measurement is not impacted by flow behavior

- Rapid measurement

- Minimal sample preparation

Limitations

- Accurate interpretation requires some up-front understanding of particles’ morphology

- Semi-quantitative

- Not able to determine particle shape