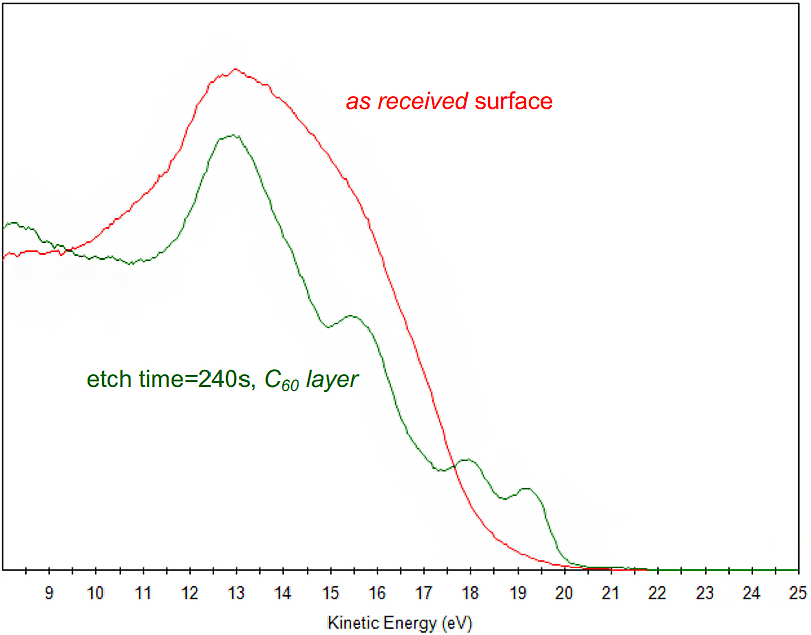

Ultraviolet Photoelectron Spectroscopy (UPS)

Ultraviolet photoelectron spectroscopy (UPS) is often performed with X-ray Photoelectron Spectroscopy (XPS), a powerful surface chemical characterization technique. Unique to UPS, its selective low-energy signal photoelectrons enable specific measurement of valence-band properties, as well as the electronic work function of the surface.

Strengths

- Very high surface specificity: information depth 2-4 nm

- Highly accurate spectral fingerprinting

- Selective valence-band signal: bonding orbital properties

- Reliable work function measurements possible

Limitations

- UPS peaks are not used for elemental quantification: degree of hybridization and extent of BE-shift is too substantial

- Robust density of electronic states / orbital occupancy typically requires Advanced Modeling

- Work function measurement requires careful setup to isolate sample low-KE cutoff from detector behavior