Recommended Strategies for Wafer Offcut Measurement in Thin Film Applications Using X-ray Diffraction (XRD)

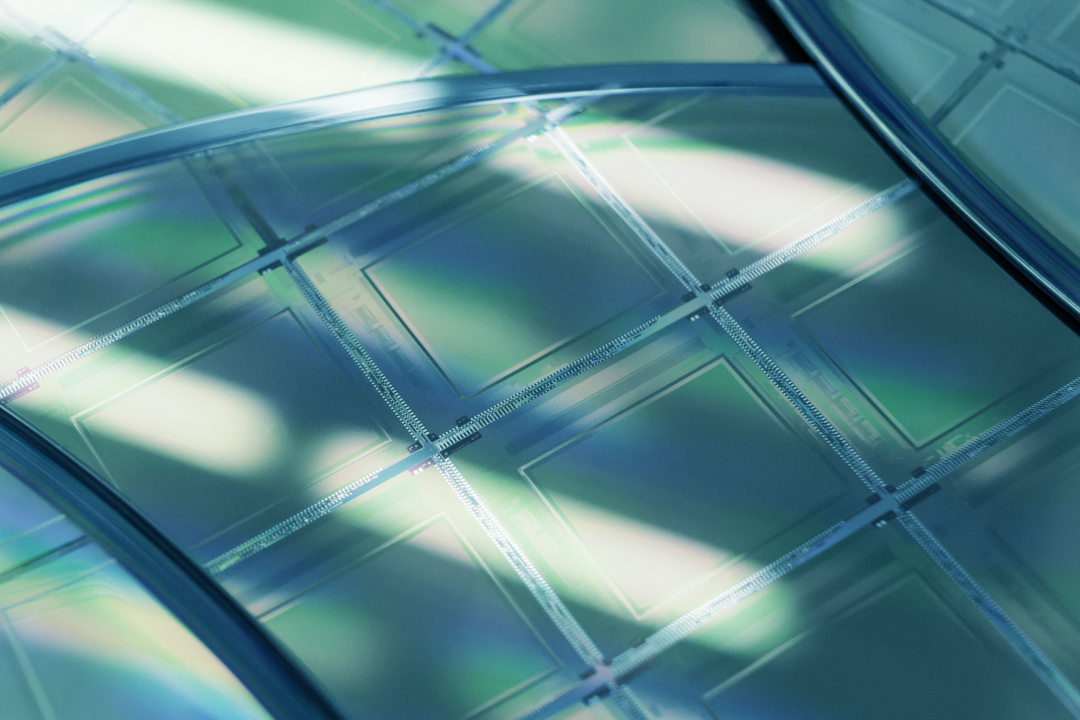

When growing epitaxial thin films on substrate wafers, it is advantageous to know their offcut angle: the angular tilt between the polished wafer surface and its crystallographic planes. In many cases where engineers are challenged to improve and control the quality of epitaxial films, this property may be overlooked; however, the optimal offcut angle will provide significant benefits in film growth. By honing an effective procedure for introducing the ideal offcut to substrates, engineers can enhance consistency and quality of epitaxial films and the devices they are used in.

X-ray Diffraction (XRD) is the standard method for accurate offcut angle measurement, and the Covalent X-ray team has worked to detail the process and help you navigate offcut analysis with confidence. Whether you are working to resolve poor epitaxial growth issues, to optimize internal processes, to enhance quality control, or even to qualify a new substrate vendor: offcut analysis can be a quick, highly-effective method to achieve your goals.

The Application Note, Covalent Metrology X-ray Diffraction Offcut Measurement, outlines the theory behind offcut analysis, and goes on to describe the industry-standard procedure for determining the offcut angle of a substrate wafer. The paper will walk you through an example measurement on a NIST standard Al2O3 wafer, explaining why four scans minimize instrumentation error and rotational variance, as well as how to calculate the offcut angle from your raw results.

You may be surprised to learn that a small offcut is actually ideal, resulting in positive growth effects such as: lowered epitaxial film dislocation densities and improved chemical uniformity.

It follows that high measurement accuracy and sensitivity are paramount to useful offcut determination. Covalent Metrology’s SmartLab XRD instrument incorporates the industry-leading X-ray detection system and a high-precision goniometer to achieve a reference peak-position accuracy of ± 0.00004 °. In the provided example measurement, we contrast the measured offcut result against the absolute values recorded for the NIST standard, demonstrating strong agreement in offcut magnitude. Importantly, as discussed in the Application Note, the orientation axes selected for measurement may vary between manufacturers and analysts; this affects only the sign of the offcut (positive or negative), not its absolute value.

If you have experienced challenges with growing epitaxial thin films or if you are interested in optimizing your substrate processing, we invite you to review Covalent’s newest Application Note to learn more about offcut measurement. It will equip you with the knowledge to approach this analysis like a pro and to start implementing it in your work successfully.

I hope this helps. Please feel free to leave comments and share your thoughts and opinions. If you have any questions that you'd like to discuss in private, please send me a LinkedIn connection invitation. Thanks!

--

Covalent Metrology’s X-ray Analysis team is led by Dr. Colleen Frazer, who has worked extensively with X-ray Diffraction and X-ray Reflectometry to perform advanced analysis in applications spanning academic institutions, national labs, and numerous private companies. Dr. Frazer and her team utilize the cutting-edge Rigaku SmartLab XRD system, equipped with the industry-leading HyPix 3000 detector and a 9kW rotating anode source for maximized signal and accuracy. With world class expertise and instrumentation, Covalent Metrology is ready to support any and all of your x-ray characterization needs.