-

Special Outsourcing Considerations for Start-ups

Special Outsourcing Considerations for Start-ups Published Over the past several weeks, I have been releasing a series of articles arguing for a new approach to analytical outsourcing. A less transactional, more partnership-oriented approach. One that is facilitated by software and new, more relationship-centric, business models. With these tweaks and updates, I believe that analytical outsourcing…

-

7 Common Outsourcing Mistakes

How to recognize and avoid 7 of the most common mistakes that impair success in outsourcing analytical services.

-

Understanding the Testing, Inspection, Certification & Compliance (TICC) Industry – and Why That Matters

Dive into the Testing, Inspection, Compliance, and Certification (TICC) industry: what it is, why it’s important, and where Covalent fits in.

-

7 Tips for Improving Your “Buy vs. Build” Analysis

How should you think through the decision of whether to outsource analysis vs. purchase, install, maintain, and support a new tool in-house?

-

Strategic Outsourcing of Metrology and Characterization

Strategic Outsourcing of Metrology and Characterization Published My job provides ample opportunity to speak with engineers, managers, and company leaders about their imaging, measurement, and characterization needs. After doing so for the past seven years, I can report confidently that very few companies have a deliberate, well-thought-out strategy for this critical corporate function. Over the…

-

Comparison of Raman Spectroscopy and Fourier Transformed Infrared (FTIR) Spectroscopy for Advanced Technology R&D and Quality Control

Increasing complexity in device and packaging materials requires a thorough understanding of the chemistry of the materials at hand. Identifying unknown materials, quantifying differences between research samples, mapping homogeneity of composition, and characterizing surface chemistry can all be paramount in the design and manufacturing processes. To meet these growing demands, a diversified group of characterization…

-

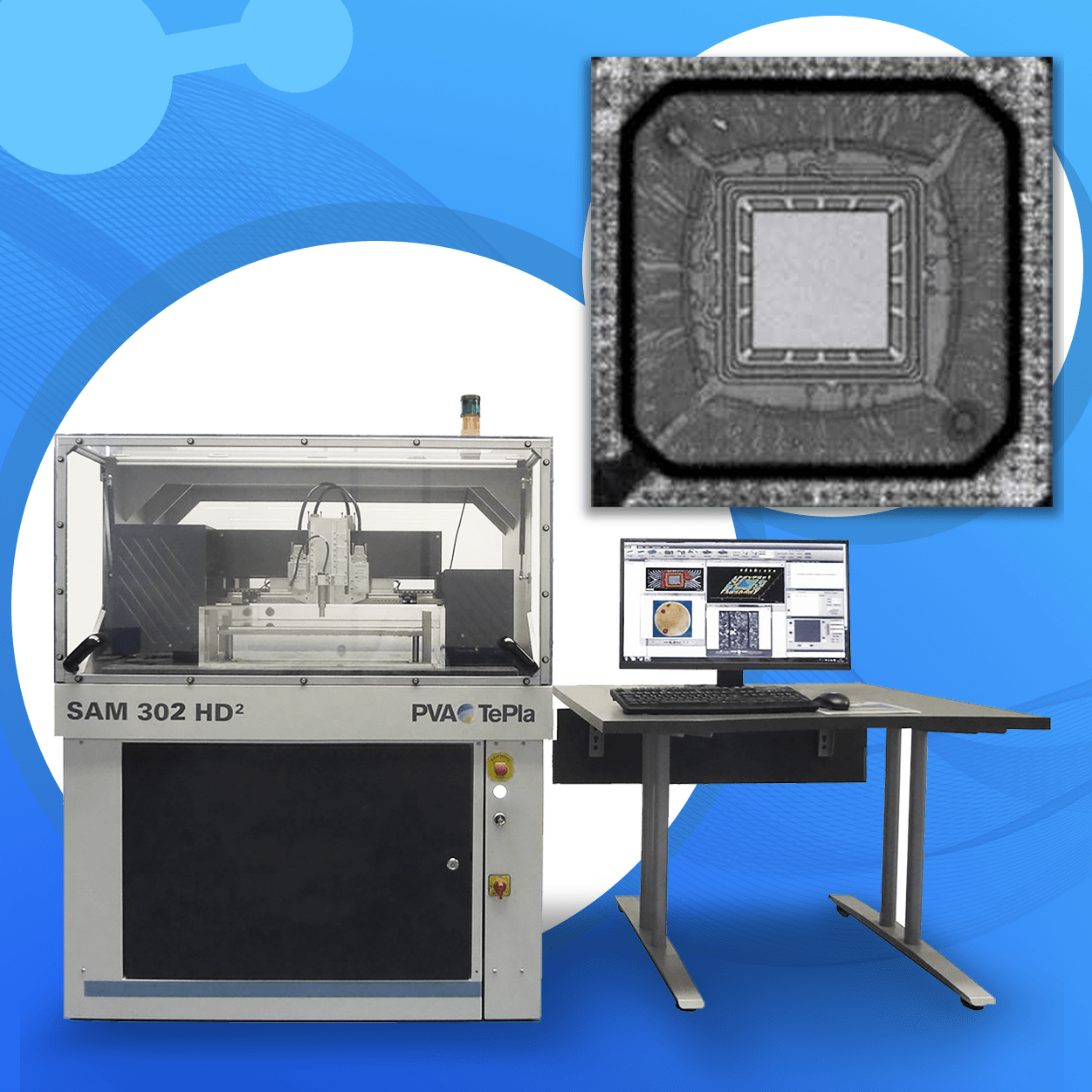

Covalent Installs Acoustic Microscope from PVATePla for Imaging Internal Device Defects

Covalent Installs Acoustic Microscope from PVATePla for Imaging Internal Device Defects The new SAM-302HD2 from PVATePla will accelerate time-to-data for scanning acoustic microscopy (SAM) and failure analysis services at Covalent Metrology. September 27, 2023 – Sunnyvale, CA. Covalent Metrology, a premiere North American provider of modern analytical services, has installed a new acoustic microscope from…

-

Covalent Metrology Joins the Silicon Catalyst In-Kind Partner Ecosystem

Covalent Metrology Joins the Silicon Catalyst In-Kind Partner Ecosystem Covalent brings 100+ modern semiconductor metrology techniques to the incubator’s network to empower next-generation start-ups May 31, 2023 – Silicon Valley, California. Silicon Catalyst, an incubator exclusively focused on accelerating semiconductor solutions, announced that Covalent Metrology has joined as a new member of its In-Kind Partner ecosystem. Covalent Metrology,…

-

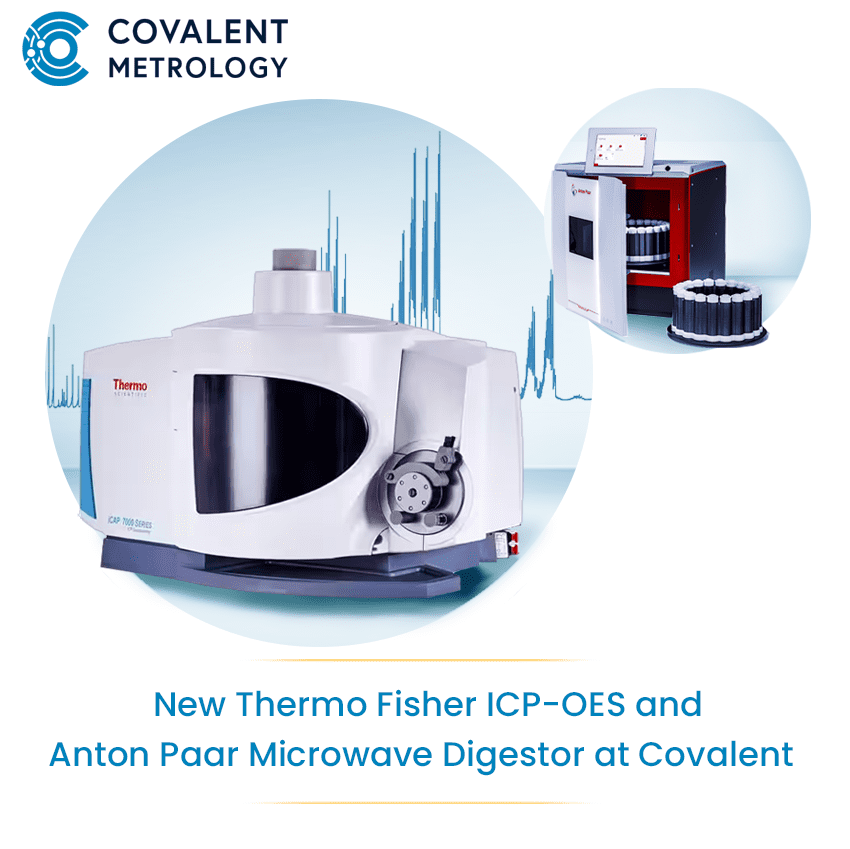

Expanded Analytical Chemistry Lab at Covalent Provides Comprehensive Testing for Solids and Liquids

Expanded Analytical Chemistry Lab at Covalent Provides Comprehensive Testing for Solids and Liquids A new ICP-OES and microwave digestor at Covalent Metrology round out its chemistry laboratory to deliver complete, modern chemical analysis for solid and liquid samples. April 4, 2023 – Sunnyvale, CA. Covalent Metrology, a top provider of premiere analytical services in North America, announced…

-

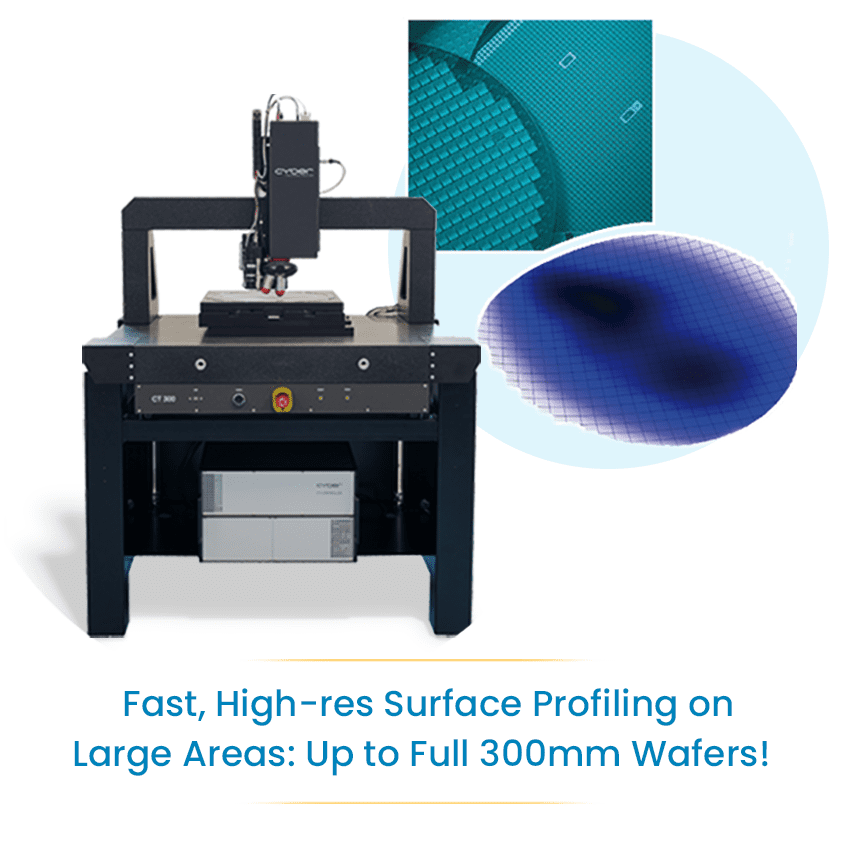

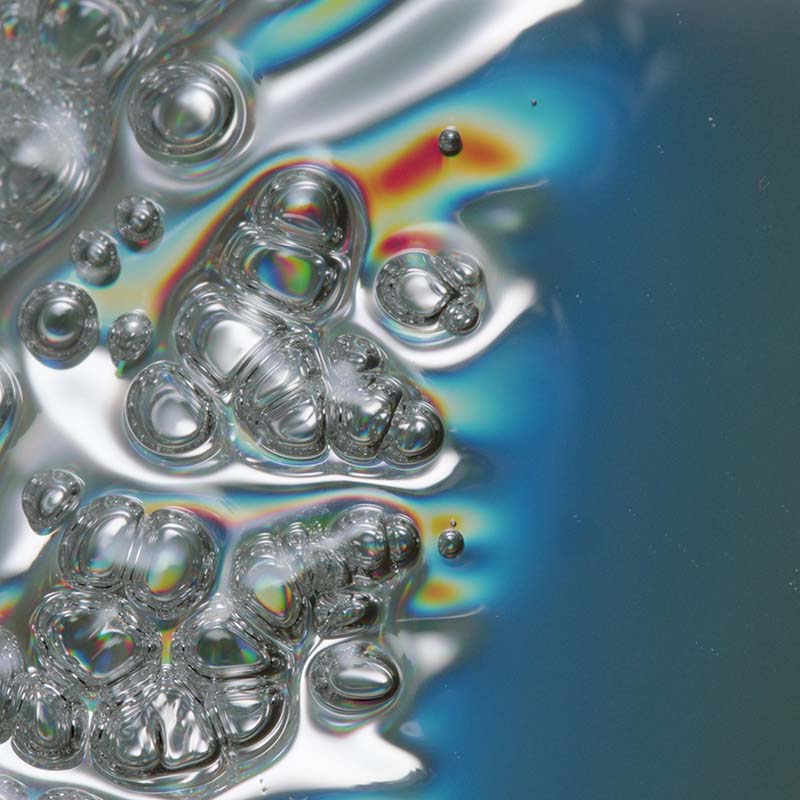

Covalent Offers Fast, High-res Surface Imaging for Full Wafers with CT300 System

Covalent Offers Fast, High-res Surface Imaging for Full Wafers with CT300 System The new, high-resolution profilometer at Covalent Metrology enables non-destructive, high-speed imaging analysis on larger and more intricate samples than ever before. March 27, 2023 – Sunnyvale, CA. Covalent Metrology, a premiere analytical services provider in North America, announced the installation of a high-speed profilometer from cyberTECHNOLOGIES,…

-

The Case for Outsourcing in the Face of Economic Uncertainty

When to outsource, and then how to do so, are each strategic choices that heavily influence the success or failure of a company’s R&D effort…

-

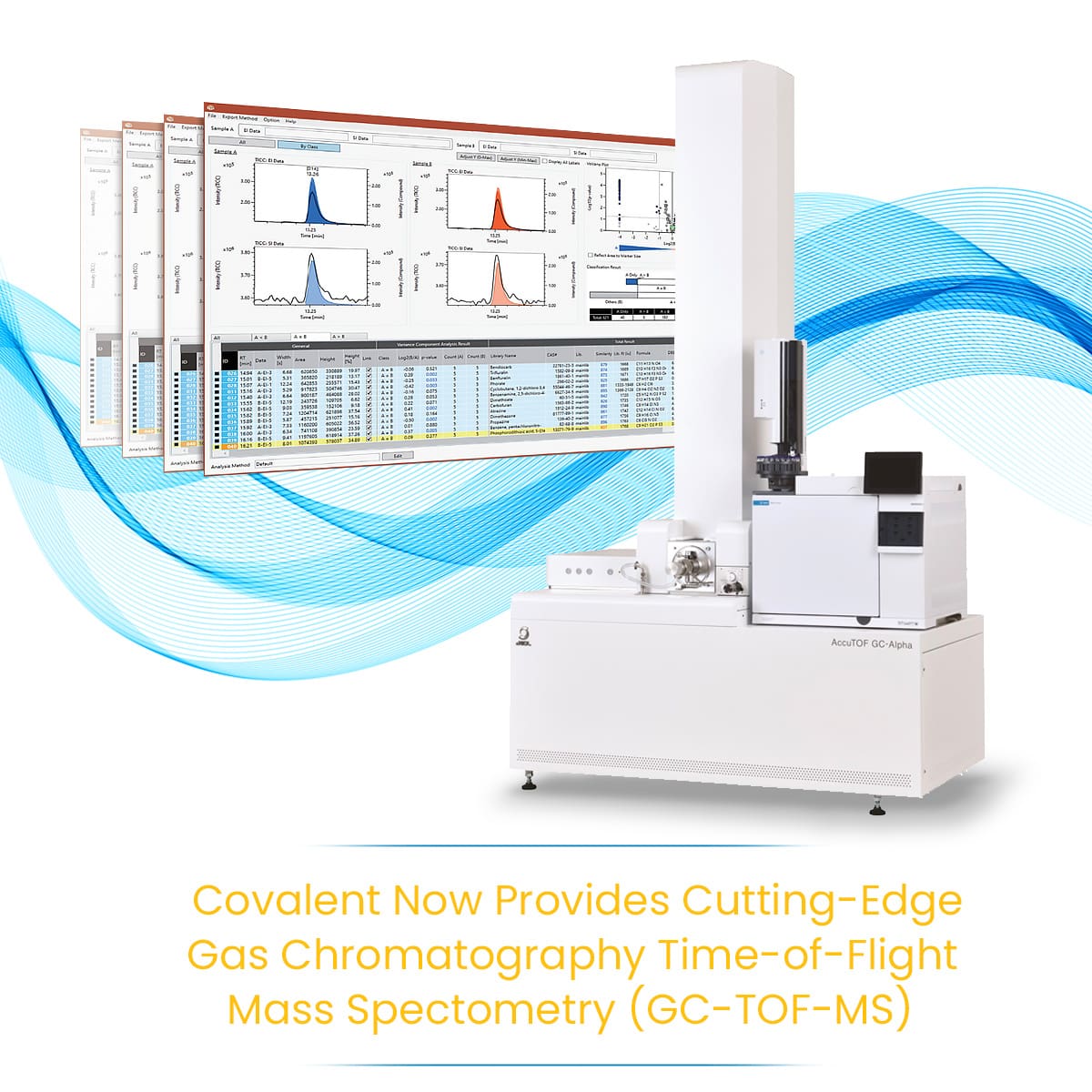

Covalent Provides Ultra-high Resolution Gas Chromatography-Mass Spectrometry (GCMS) with New Spectrometer from JEOL

Covalent Provides Ultra-high Resolution Gas Chromatography-Mass Spectrometry (GCMS) with New Spectrometer from JEOL The JEOL AccuTOF GC-Alpha installed at Covalent Metrology pushes the limits of mass spectrometry services to deliver enhanced data quality and speed September 1, 2022 – Sunnyvale, CA. Covalent Metrology, a North-American provider of premier analytical services, announced significant enhancements to its mass spectrometry…

-

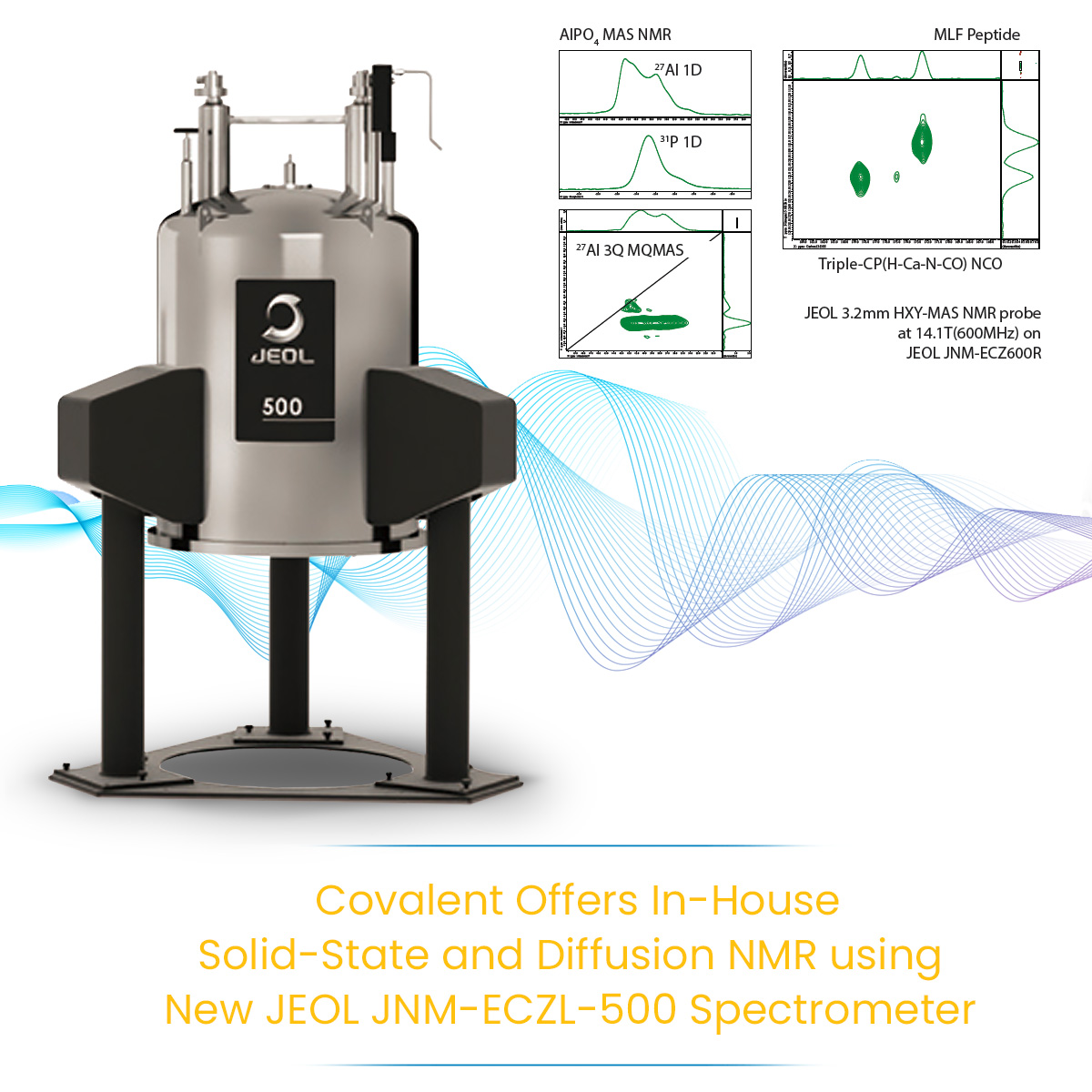

Covalent Metrology Offers Nuclear Magnetic Resonance (NMR) Services with New Spectrometer from JEOL

Covalent Metrology Offers Nuclear Magnetic Resonance (NMR) Services with New Spectrometer from JEOL The installation of the JEOL JNM-ECZL-500 NMR Spectrometer enables Covalent to support clients with faster and more flexible NMR analysis August 11, 2022 – Sunnyvale, CA. Covalent Metrology, a leading North-American provider of analytical services, announced the installation of a new 500 MHz Nuclear…

-

4 Targets for Optimization in a Battery Cell

Read about four common targets for battery optimization and how you can access the data and insight necessary to optimize in these areas.

-

Battery Optimization Empowered by Strategic Metrology and Characterization

How can scientists and engineers optimize battery cells to meet growing industrial demand? See how analytical data supercharges battery R&D.

-

CT vs SEM: 10 Comparisons for Subsurface Imaging Analysis

This blog dives into 10 points of comparison between the strengths and applications of micro-CT and SEM for subsurface imaging analysis.

-

CT vs SEM: Which is Better?

Contrast the capabilities of micro-CT and SEM: explore their strengths and learn when to use each technique to get the insight you need.

-

Covalent Metrology Installs New CFEG TEM Equipped for High-Resolution EELS and EFTEM

Covalent Metrology Installs New CFEG TEM Equipped for High-Resolution EELS and EFTEM Covalent completes installation of a new, cutting-edge JEOL JEM-F200 microscope with a cold-field-emission gun (CFEG) source and a Gatan Imaging Filter for EELS and EFTEM. June 21, 2022 – Sunnyvale, CA. Covalent Metrology, a leading North-American analytical services provider, announced today that it has significantly…

-

The Age of (Scanning) Transmission Electron Microscopy is Here

Covalent’s Director of S/TEM Analysis, Jason Donald, introduces Covalent’s latest eBook: Age of (Scanning) Transmission Electron Microscopy.

-

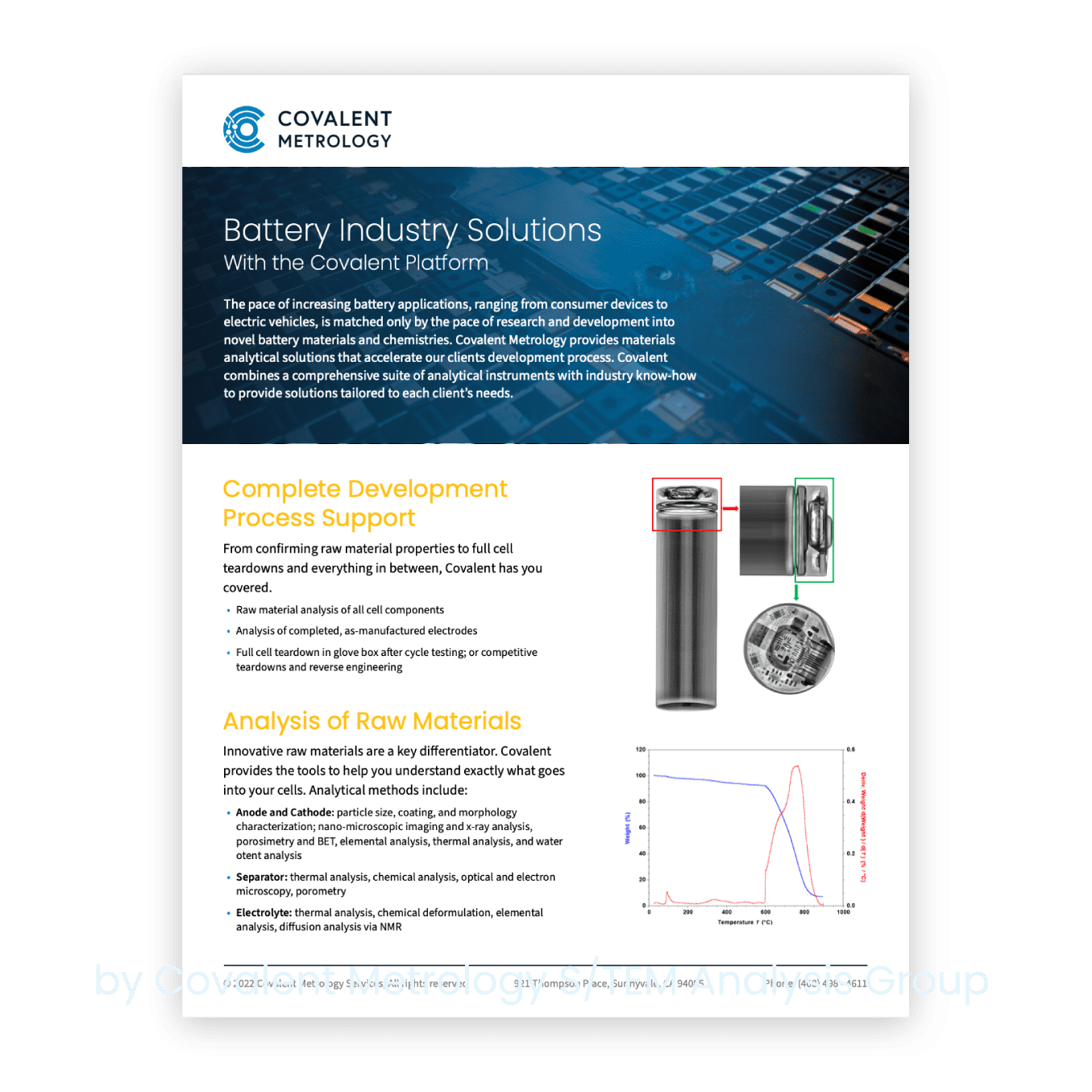

Batteries Industry Solutions with the Covalent Platform

Learn about Covalent’s metrology solutions supporting the design and development of new technologies and materials in the battery industry.

-

Age of (Scanning) Transmission Electron Microscopy

Age of (Scanning) Transmission Electron Microscopy Click below to download this eBook In this overview eBook, Covalent Metrology’s team of expert electron microscopists summarize the fundamentals of (Scanning) Transmission Electron Microscopy (S/TEM). Download the eBook now to learn about the inner workings of S/TEM instruments, key principles for effective sample preparation, and select application areas of this…

-

Happy World Metrology Day to the Unsung Heroes

We’re taking a moment to pause and be grateful for all our great Metrologists. Happy World Metrology Day to you all!

-

Porous Materials Characterization with Porometry, Porosimetry, and Pycnometry

These excerpts of Covalent Academy’s webinar on porous materials characterization introduce 3 of the most common techniques in this field.

-

Key Principles of Lamella Sample Preparation for Scanning Transmission Electron Microscopy (S/TEM)

Video walkthroughs of key methods and considerations for preparing high-quality S/TEM lamella using a DualBeam FIB-SEM microscope.

-

(Scanning) Transmission Electron Microscopy (S/TEM) Using the Thermo Fisher Talos F200X

Learn about the fundamentals of S/TEM analysis with the Talos F200X: imaging modes and signals, detector setup, and principles of operation.

-

Electron and Ion Beam Imaging with DualBeam Focused Ion Beam Scanning Electron Microscopes

View video examples that walk through the electron- and ion-beam imaging modes available on TFS DualBeam electron microscopes.

-

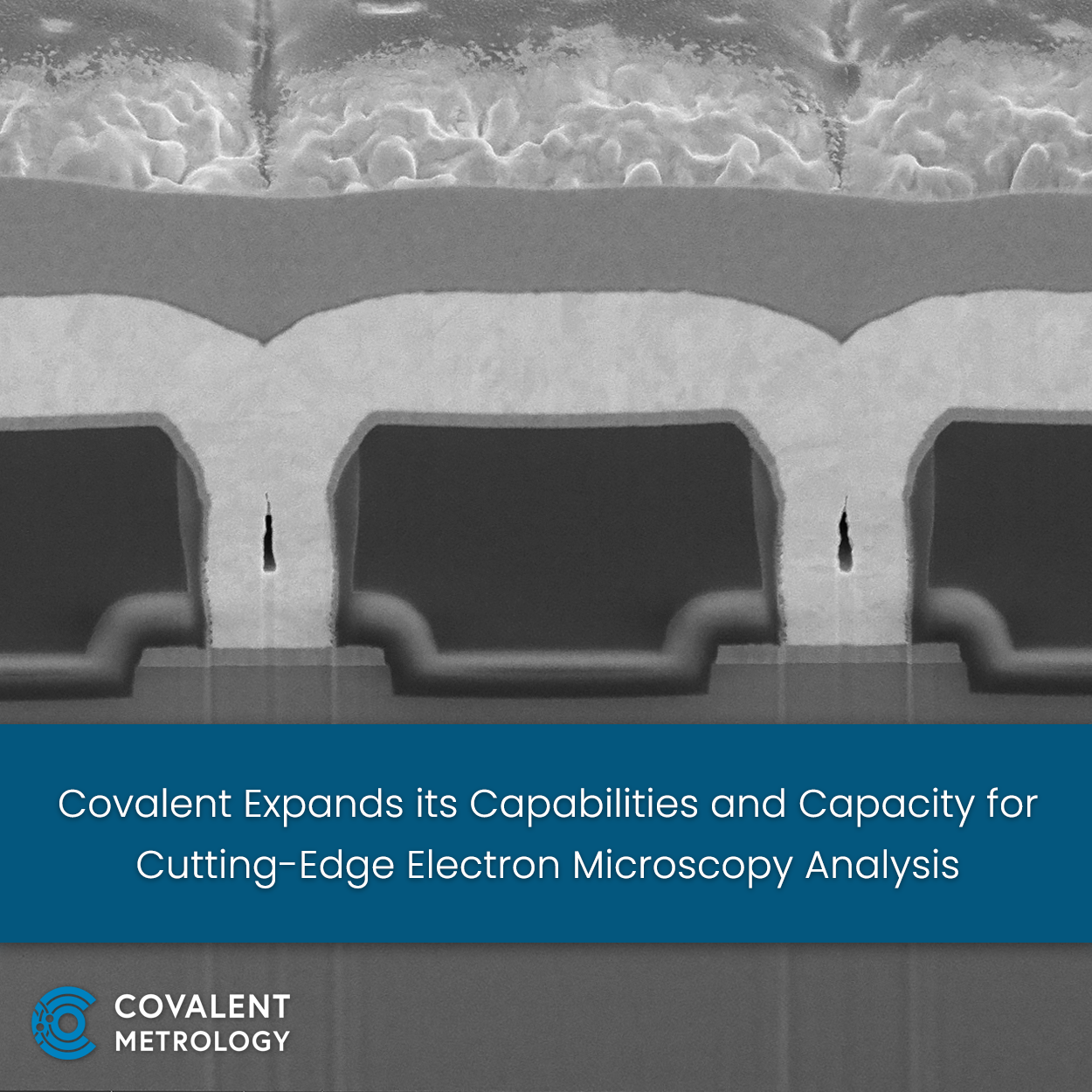

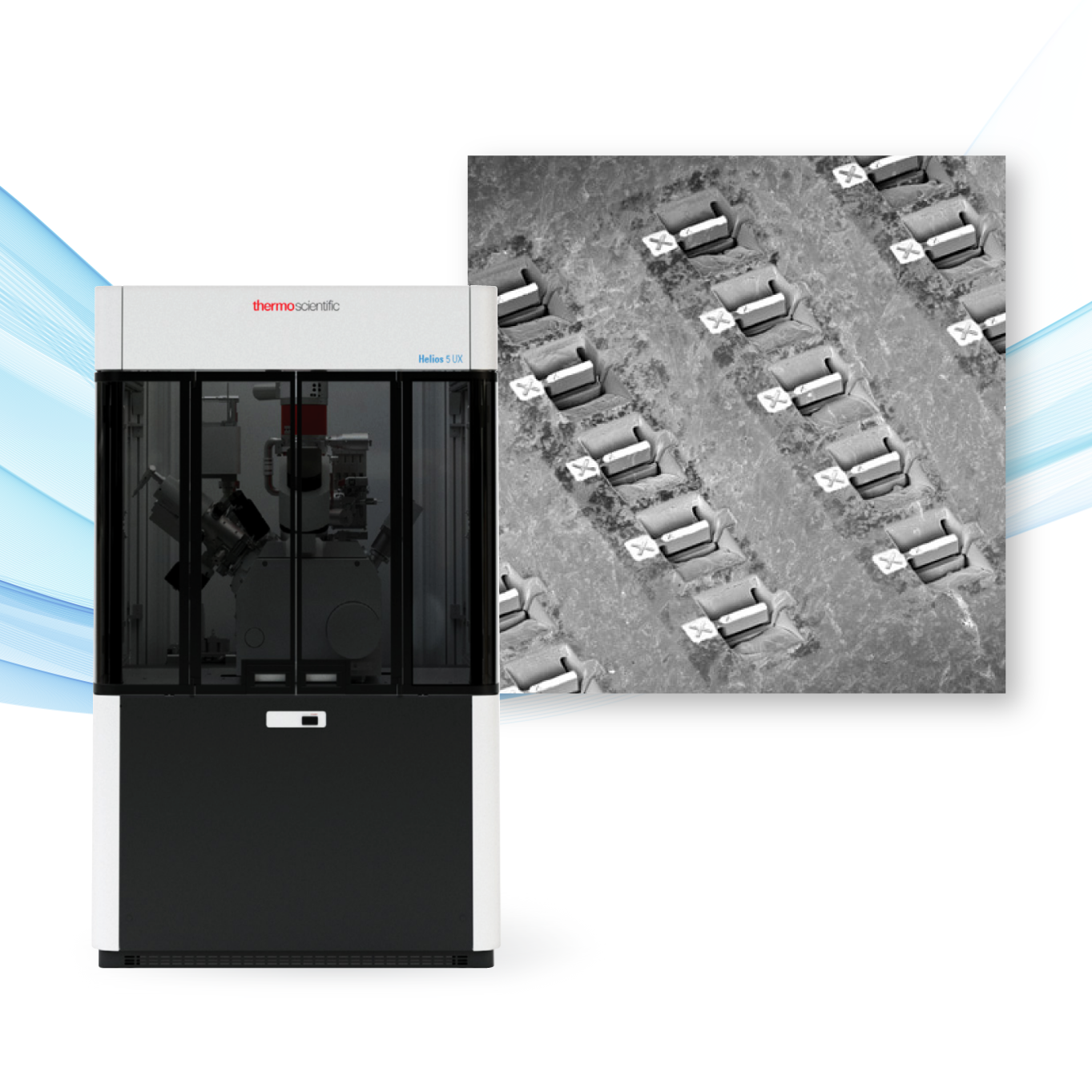

Covalent Metrology Expands its Electron Microscopy Capabilities

Covalent Metrology Expands its Electron Microscopy Capabilities The Growing Electron Microscopy Group at Covalent’s Silicon Valley lab significantly expands its team and instrument portfolio for FIB-SEM and S/TEM analysis. April 14, 2022 – Sunnyvale, CA. Covalent Metrology, a leading provider of analytical services in North America, announces the installation of two new Thermo Fisher Scientific Helios 5…

-

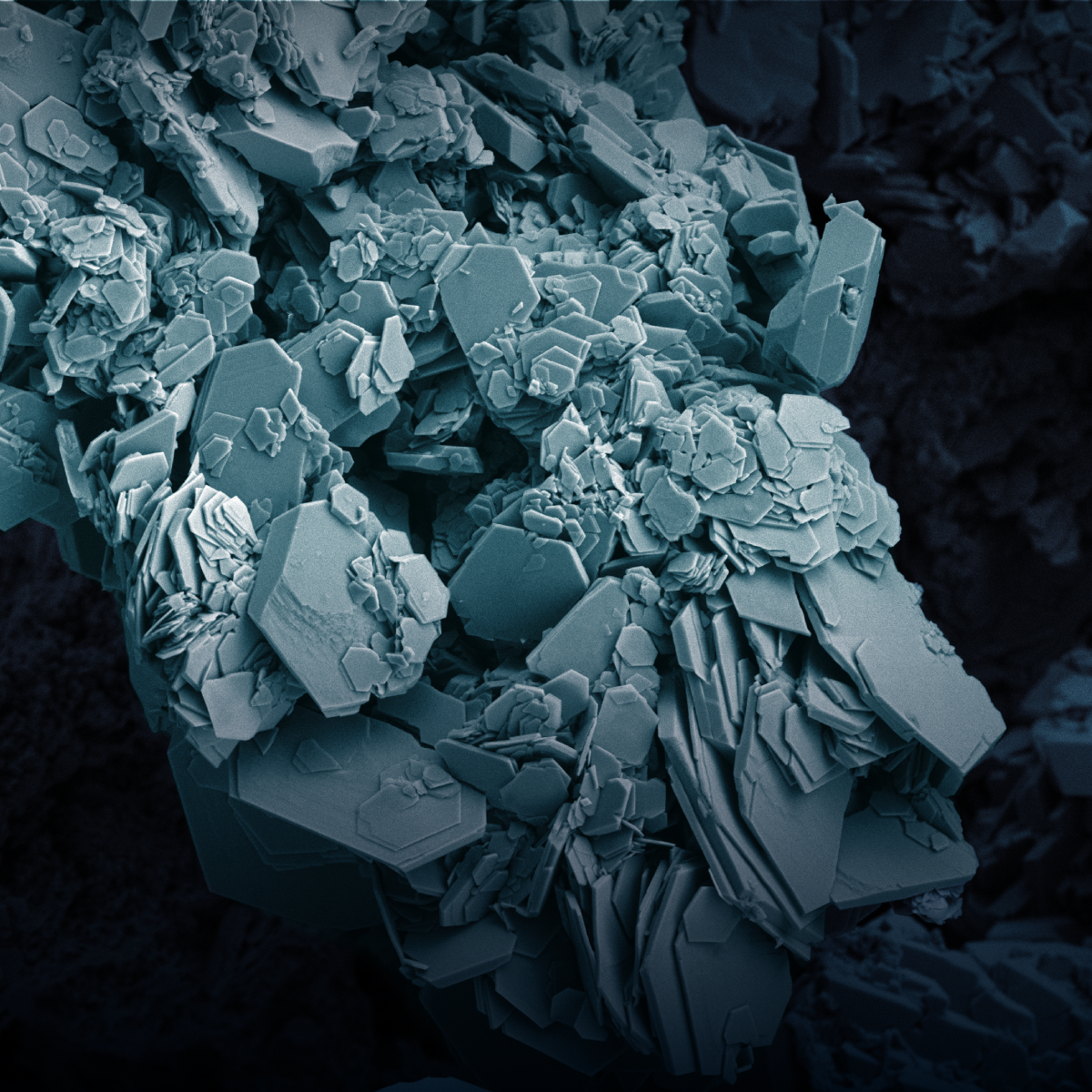

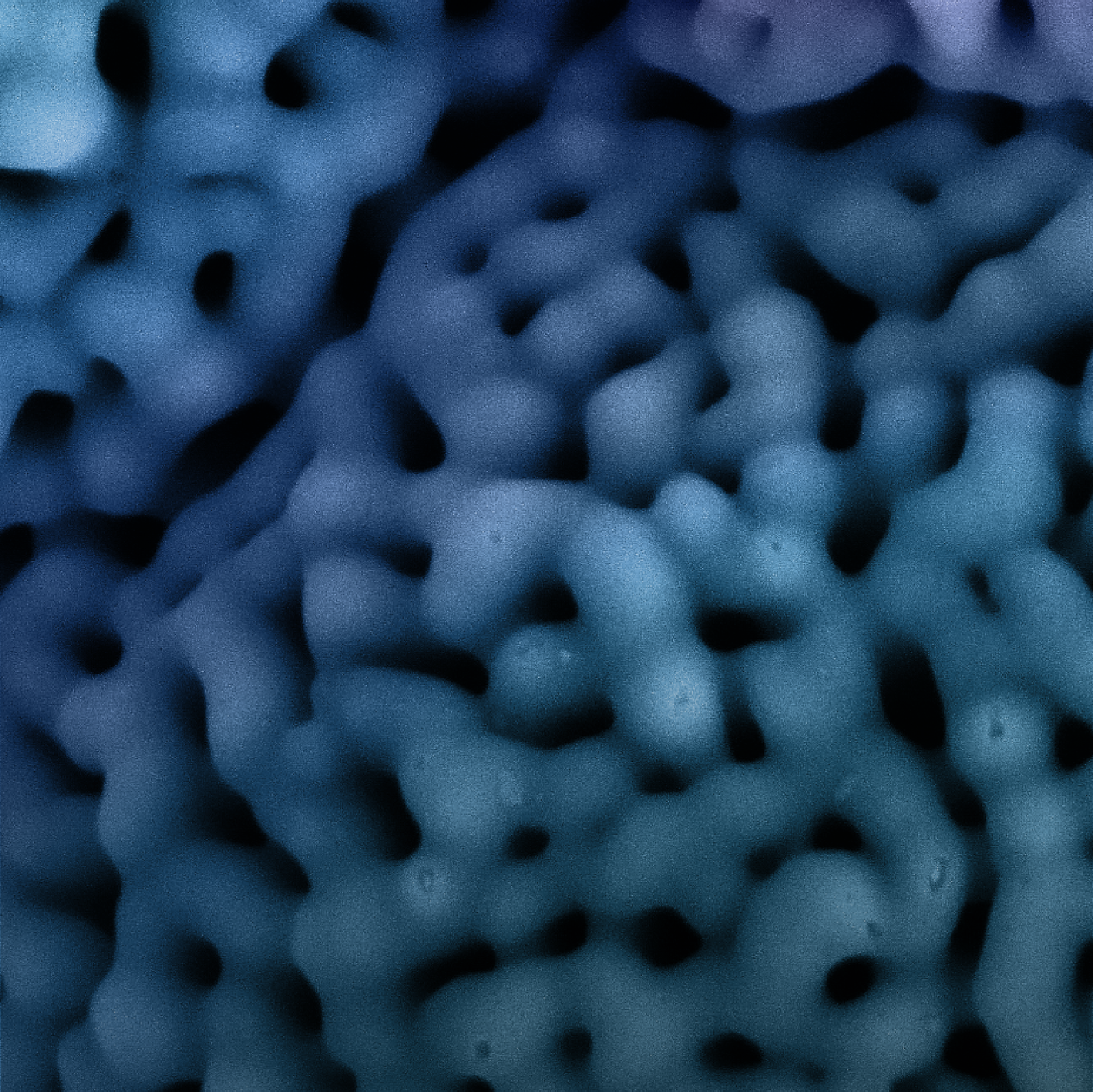

Scanning Electron Microscope (SEM) Optimization & Analysis

This eBook will help you gain great insights into SEM operation and optimization so you can feel more confident in your future SEM projects.

-

Gain Confidence in Scanning Electron Microscope (SEM) Optimization & Analysis

Introducing a new eBook from Covalent’s EM experts that will help you gain insights into SEM operation to build confidence in future projects.

-

Covalent Metrology’s Failure Analysis Group Delivers Enhanced X-Ray Inspection Services

-

Are You Using the Right Detector? 4 Things to Remember for SEM

Learn about the different types of detectors on SEM tools as well as four operational ideas to remember to optimize your SEM analysis.

-

Pulsed RF Glow Discharge Optical Emission Spectroscopy eBook

HORIBA’s Pulsed RF GDOES gives comprehensive element analysis by combining high-res GD optics with a pulsed-RF plasma source…

-

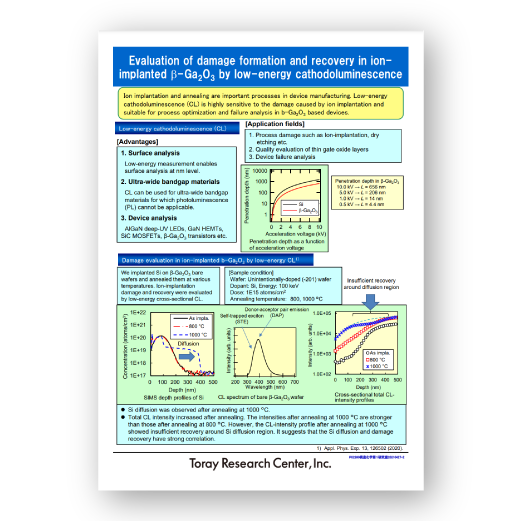

Evaluation of Damage Formation and Recovery in Ion Implanted Beta-Ga2O3 by Low Energy Cathodoluminescence

Low-energy cathodoluminescence (CL) is highly sensitive to ion implantation damage, making it useful for optimizing Beta-Ga2O3 devices.

-

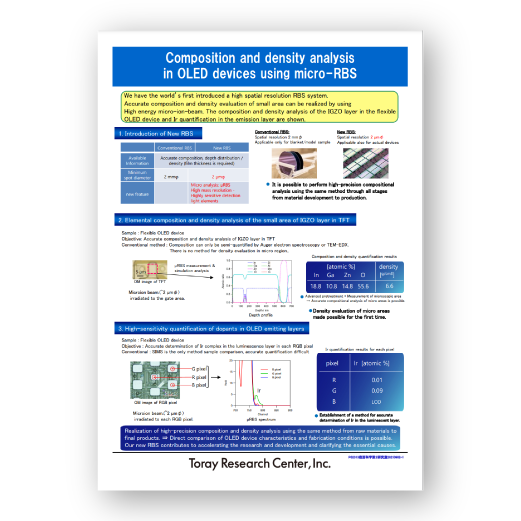

Composition and Density Analysis in OLED Devices Using Micro-RBS

This white paper summarizes how Rutherford Backscattering Spectroscopy (RBS) is used to analyze the composition and density of OLED devices.

-

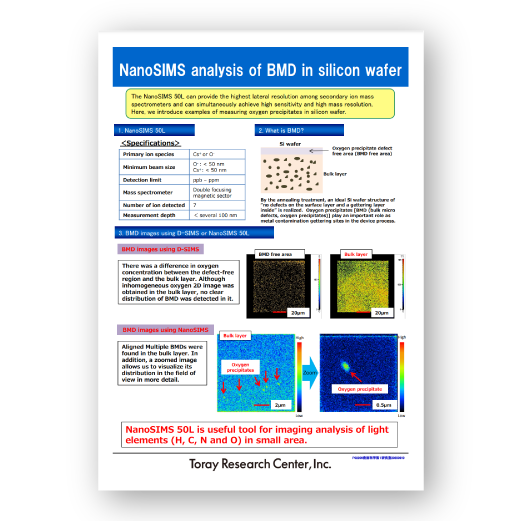

NanoSIMS Analysis of BMD in Silicon Wafer

This white paper from Toray Research Center introduces how NanoSIMS can be used to measure oxygen precipitates in a silicon wafer.

-

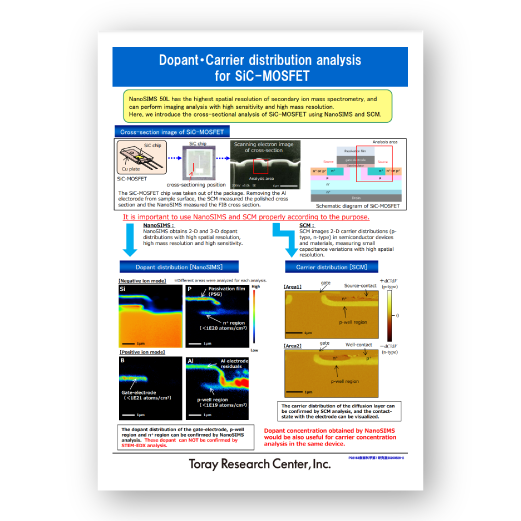

Dopant Carrier distribution analysis for SiC-MOSFET

This white paper summarizes how the high spatial resolution of the NanoSIMS 50L system facilitates dopant carrier distribution analysis.

-

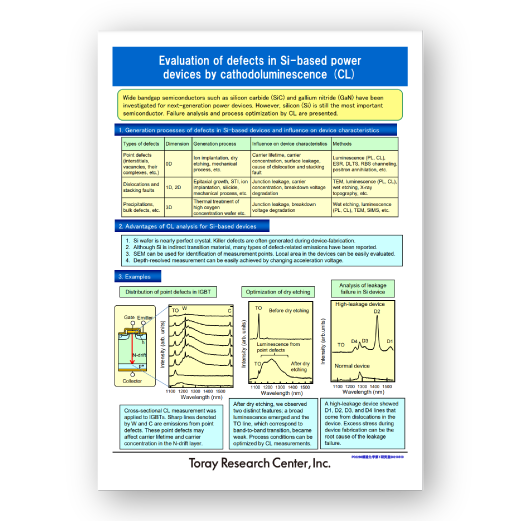

Evaluation of Defects in Si-based Power Devices by Cathodoluminescence (CL)

This white paper describes the use of Cathodoluminescence in SEM for failure analysis and process optimization of semiconductor devices.

-

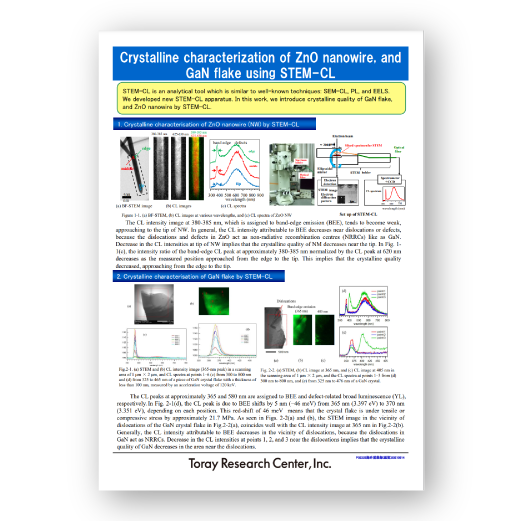

Crystalline Characterization of ZnO Nanowire and GaN Flake using STEM-CL

In this work, Toray Research Center introduces crystalline quality to GaN flakes and ZnO nanowires by STEM-CL.

-

Covalent Metrology and JEOL Announce Partnership, Silicon Valley Demonstration Facility

Covalent Metrology and JEOL Announce Partnership, Silicon Valley Demonstration Facility The two leaders announced a partnership that includes a new JEOL demonstration facility located in Covalent’s Silicon Valley lab. The partnership will accelerate applications development and broaden client access to a suite of state-of-art instrumentation and analytical services. December 07, 2021 – Sunnyvale, CA. Covalent Metrology, a…

-

Covalent Metrology Installs the Latest FIB/SEM Lamella Sample Preparation Instrument

Covalent Metrology Installs the Latest FIB/SEM Lamella Sample Preparation Instrument The Silicon Valley lab expands its electron microscopy capabilities with industry leading S/TEM lamella sample preparation on the newly installed Thermo Scientific Helios 5 UX DualBeam instrument. November 15, 2021 – Sunnyvale, CA. Covalent Metrology, a leading North American provider of analytical services, announces the installation of…

-

Covalent Metrology Announces New Semiconductor Consulting Practice Group

Covalent Metrology Announces New Semiconductor Consulting Practice Group The Silicon Valley company to offer custom metrology solutions for advanced semiconductor applications to be led by industry expert Dr. Yihung Lin. November 4, 2021 – Sunnyvale, CA. Covalent Metrology, a leading North American analytical services company located in the heart of Silicon Valley, announced that it has formed…

-

Covalent Metrology Announces Analytical Services Partnership with Toray Research Center, Inc.

Covalent Metrology Announces Analytical Services Partnership with Toray Research Center, Inc. The partnership provides expanded analytical services for new advanced material and product applications for semiconductor and battery industries. October 27, 2021 – Sunnyvale, CA. Covalent Metrology (Silicon Valley California) and Toray Research Center, Inc. (Tokyo, Japan) are partnering to deliver highly advanced analytical chemistry capabilities. Bolstering Covalent’s vast…

-

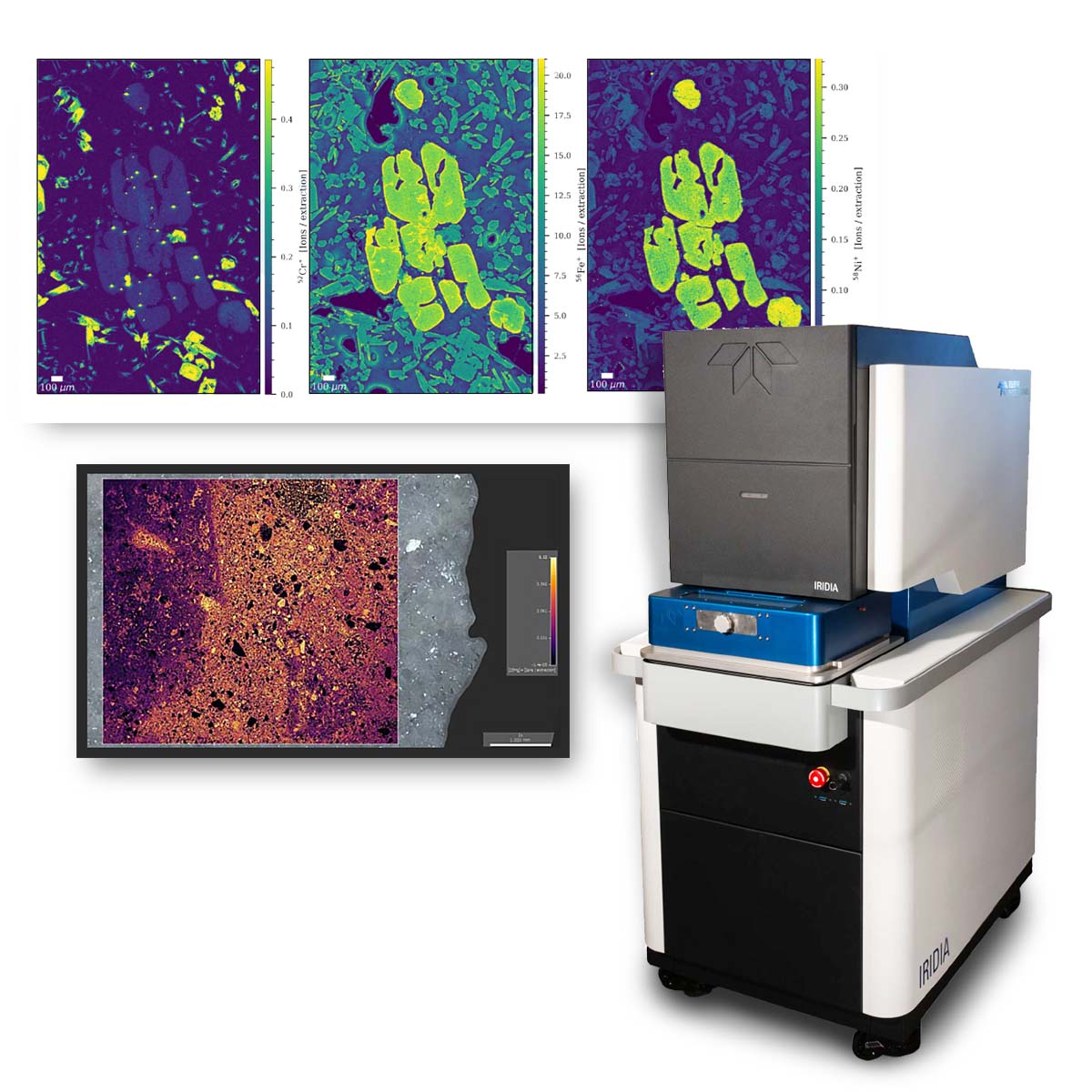

Covalent Metrology and Teledyne CETAC Technologies Announce New Partnership to Advance Research in Analytical Chemistry Applications and Instrumentation

Covalent Metrology and Teledyne CETAC Technologies Announce New Partnership to Advance Research in Analytical Chemistry Applications and Instrumentation Partners jointly announce the installation of a new Teledyne Photon Machine’s Iridia Laser Ablation system at Covalent Metrology’s Silicon Valley headquarters. October 12, 2021 – Sunnyvale, CA. Covalent Metrology, a leading North American provider of analytical services, has partnered…

-

Explore Thermal Characterization Techniques: TGA and DSC

These videos explain the mechanism behind Thermogravimetric Analysis (TGA) and Differential Scanning Calorimetry (DSC).

-

Enhance Your X-ray Reflectometry Skills

These videos from Dr. Colleen Frazer walk you through experimental setup and analysis on thin films using X-ray Reflectometry.

-

Examples of 3D Reconstruction with FIB-SEM Tomography

These short videos from guest presenter Rick Passey showcase example applications for 3D reconstructions generated using FIB-SEM tomography.

-

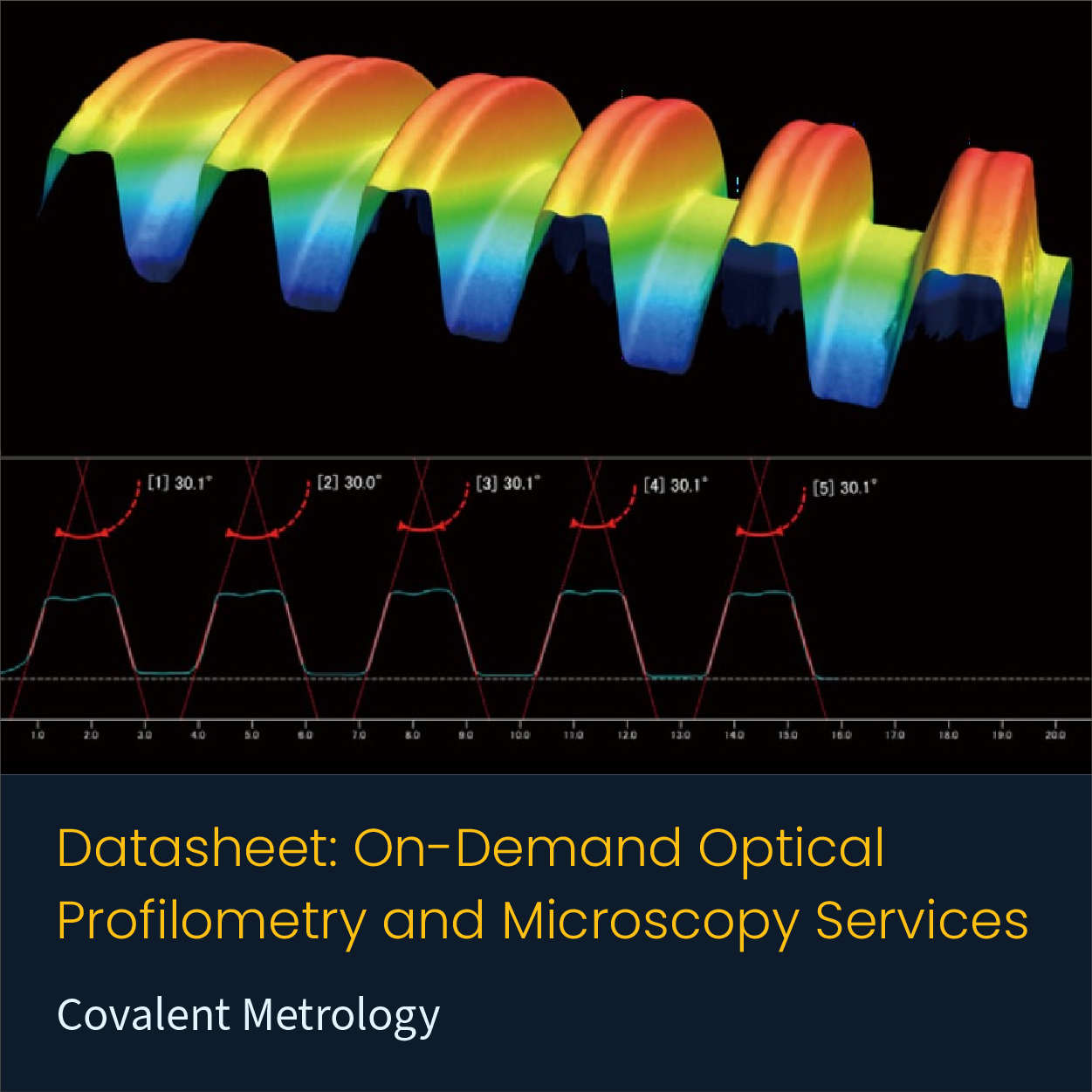

Optical Microscopy and Profilometry Services

Covalent’s non-contact, non-destructive optical profilometry techniques generate fast, quantitative insight into the morphology of materials.

-

Scanning Probe Microscopy Services

Scanning probe microscopy can deliver high-resolution, quantitative, and impactful data with fast and reliable turnaround times.

-

Analytical Chemistry Services

Covalent’s analytical chemistry experts use state-of-art spectroscopy tools to measure composition and probe molecular structures.

-

Failure Analysis Services

Covalent helps clients resolve challenging failure analysis questions with cutting-edge tools and 100+ years of combined FA experience.

-

Scanning Electron Microscopy with Focused Ion Beam Services

Electron microscopy provides ultra-high-resolution and enables the correlation of structural information with maps of elemental distribution.

-

(Scanning) Transmission Electron Microscopy Services

Maximize Transmission Electron Microscopy (TEM) analysis with Covalent’s cutting-edge tools and expert operation, yielding atomic resolution.

-

Differentiating Filters/Membranes by Capillary Flow Porometry

This application report compares and contrasts the results for two similar looking filters used to remove contaminants from an in-house air source.

-

Surface Area of Magnesium Stearate Using the Volumetric Method

The NOVAtouch is ideal for specific surface area measurements according to the volumetric method and the well-known BET calculation.

-

Solid Density of Building Materials: Assessing Purity of Powders and Open Porosity of Concrete Components

Solid Density of Building Materials: Assessing Purity of Powders and Open Porosity of Concrete Components The density of building materials such as cement and bitumen plays a significant role in production and performance. Purity of powders and the open porosity of cured pieces are important material characteristics that can be assessed from solid density measurements.…

-

Using Gas Pycnometry to Determine Polymer Crystallinity

Gas pycnometry can be used to assess the skeletal density of polymer materials, which can then be related to the crystallinity.

-

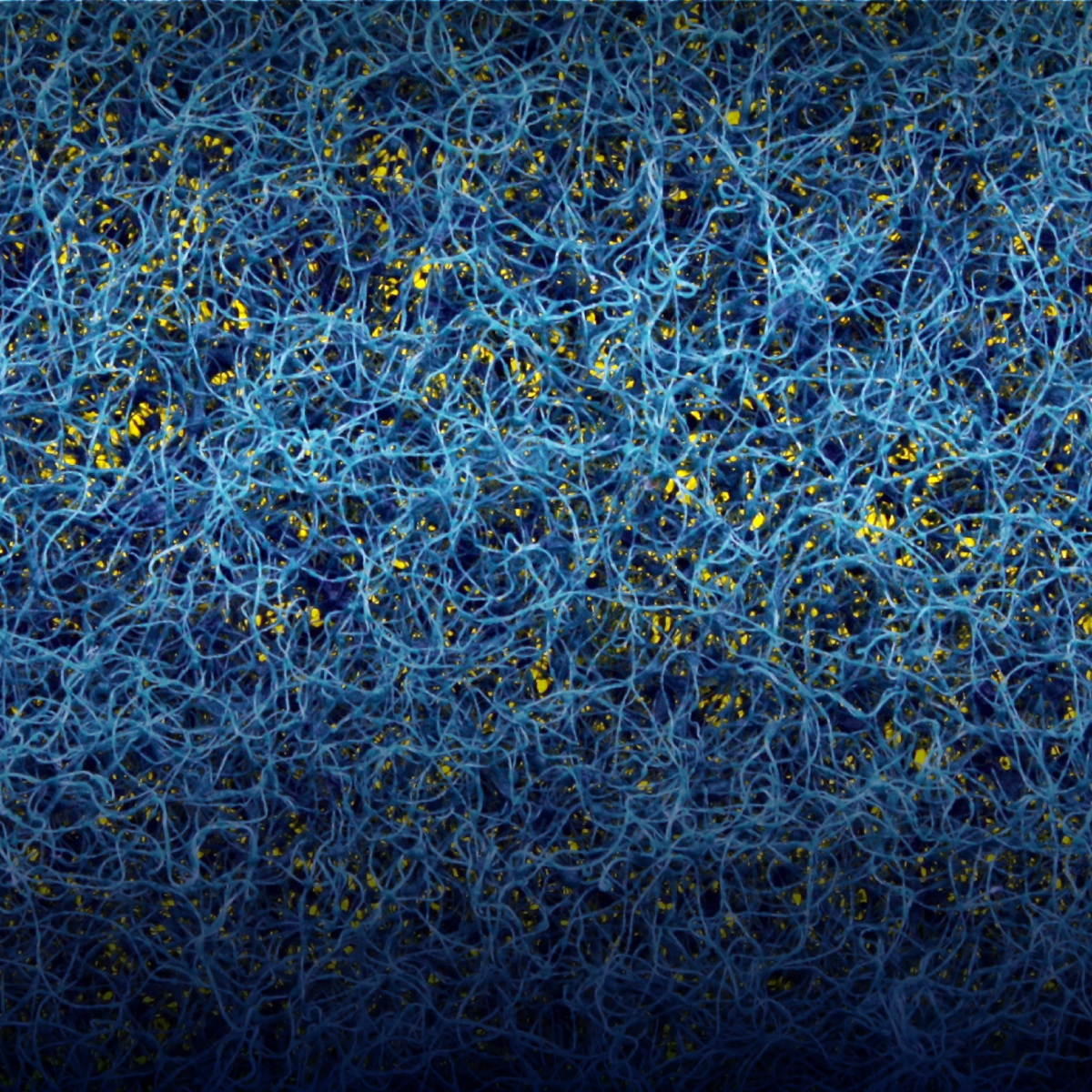

Structural Characterization of Battery Components

Examples of gas sorption, mercury intrusion, and capillary flow porometry for anode, cathode, and separator materials, among others, are here discussed.

-

Analysis of PTFE: Why does it seal well?

This paper shows how PFTE can be analyzed at a textural level to completely explanation of its physical, real world performance attributes.

-

Graphene Characterization

This note describes the use of gas sorption (porosimetry) for the characterization of the texture and pore structure of graphene.

-

3 Scanning Electron Microscopy (SEM) Signals You Need to Know to Optimize Your SEM Analysis

Understanding and optimizing Scanning Electron Microscopy (SEM) signals allows researchers to maximize the insight extracted from micrographs.

-

Atomic Force Microscopy for Advanced Optical Components

In this white paper, Covalent experts explain the benefits of Atomic Force Microscopy (AFM) for high-resolution surface characterization.

-

Mid-Range Optical Profilometry Overview

This overview summarizes the technical mechanism behind some of the most popular optical profilometry techniques in surface analysis.

-

Medical Device Characterization with the Covalent Platform

This datasheet presents an overview of the analytical solutions and services Covalent offers for medical device characterization.

-

How to quantify GDOES depth profile data using XRF

A new method to quantify GDOES data using XRF information is presented in this application note, illuminating composition and layer thickness.

-

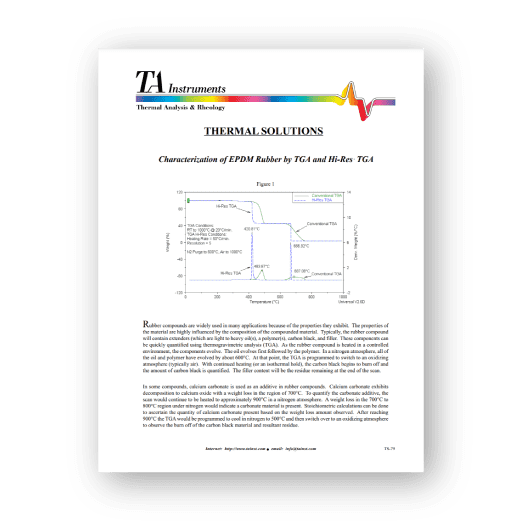

Characterization of EPDM Rubber by TGA and Hi-Res TGA

Extender compounds in Rubber (filler, carbon black, heavy oils, etc.) can be quickly quantified using thermogravimetric analysis (TGA).

-

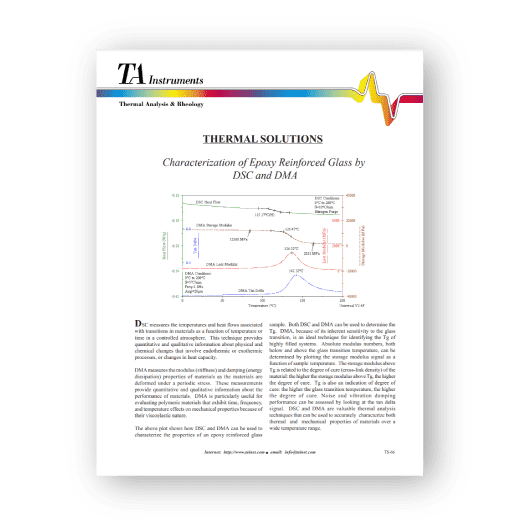

Thermal Solutions: Characterization of Epoxy Reinforced Glass by DSC and DMA

Differential Scanning Calorimetry (DSC) and Dynamic Mechanical Analysis (DMA) yield quantitative and qualitative insight into thermomechanical responses of materials.

-

Thermal Solutions: Characterization of Polyurethane by TGA and Hi-Res TGA

This example clearly shows how Hi-Res TGA can give better results, often in a shorter amount of time, than a standard TGA experiment.

-

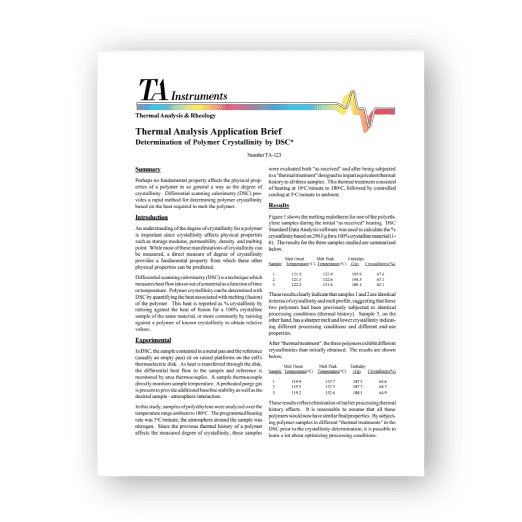

Thermal Analysis Application Brief Determination of Polymer Crystallinity by DSC

Differential scanning calorimetry (DSC) can rapidly determine a polymer’s crystallinity based on the heat required to melt the polymer.

-

TGA-IR Analysis Using the OMNIC Mercury TGA Software

This White Paper describes the TGA-IR experiment and then focuses on the infrared data analysis with the OMNIC Mercury TGA software.

-

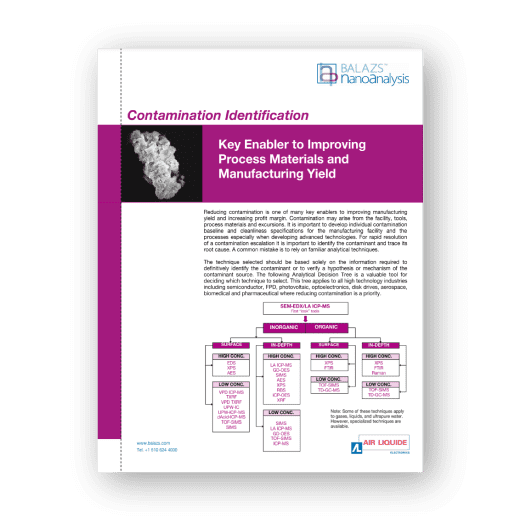

Contamination Identification

This eBrief describes how to strategize a metrology regimen to identify the species and source of contamination when it occurs in materials.

-

Printed Circuit Board Assembly (PCBA) Characterization by Destructive Physical Analysis (DPA)

Printed Circuit Board Assembly (PCBA) Characterization by Destructive Physical Analysis (DPA) Click below to download this eBook The best-known method to test the quality of printed circuit boards and their components is Destructive Physical Analysis (DPA). This process yields a comprehensive quality assessment for workmanship on PCBAs, and involves both non-destructive and destructive inspections using…

-

Covalent Keyence Instrument Overview

Review the Keyence microscopes and profilometers at Covalent! Keyence is a global leader in developing high-resolution optical imaging tools.

-

Choosing the Right Surface Imaging Technique

This eBrief presents quick and easy guidance for identifying the appropriate surface imaging solution for your samples and application.

-

7 Myths About Modern TEM

In this quick-read eBrief, Covalent’s experts clarify 7 commonly held misunderstandings about modern transmission electron microscopy (TEM).

-

Covalent Busts 7 Common Myths about Modern TEM

Learn how to avoid common misconceptions about transmission electron microscopy (TEM) so you can take this technique further in your work!

-

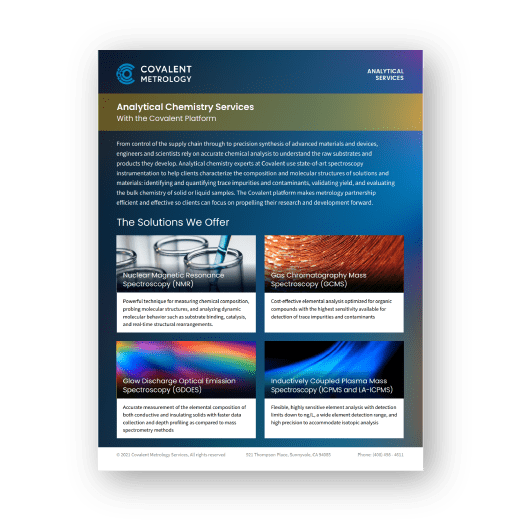

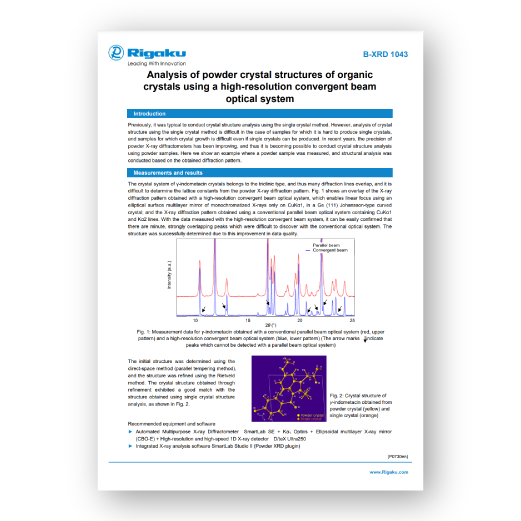

Analysis of powder crystal structures of organic crystals using a high-resolution convergent beam optical system

Analysis of powder crystal structures of organic crystals using a high-resolution convergent beam optical system ABSTRACT Previously, it was typical to conduct crystal structure analysis using the single crystal method. However, analysis of crystal structure using the single crystal method is difficult in the case of samples for which it is hard to produce single…

-

Fast, flexible stress measurements

This brochure/datasheet from Rigaku provides a high-level overview into the technology and capabilities of their SmartLab XRD system.

-

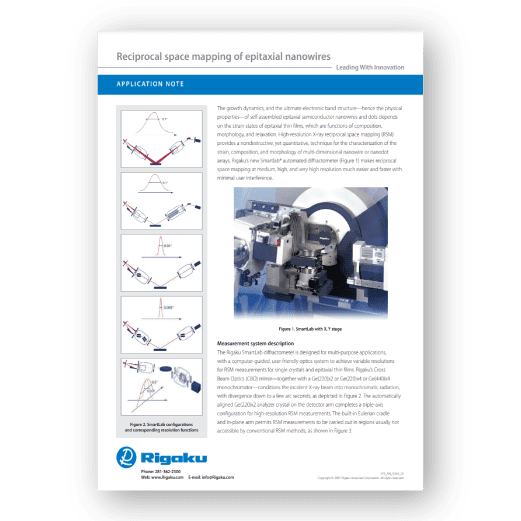

Reciprocal space mapping of epitaxial nanowires

In this app note, Rigaku experts demonstrate the exceptional power of their new SmartLab XRD system in reciprocal space mapping of nanowires.

-

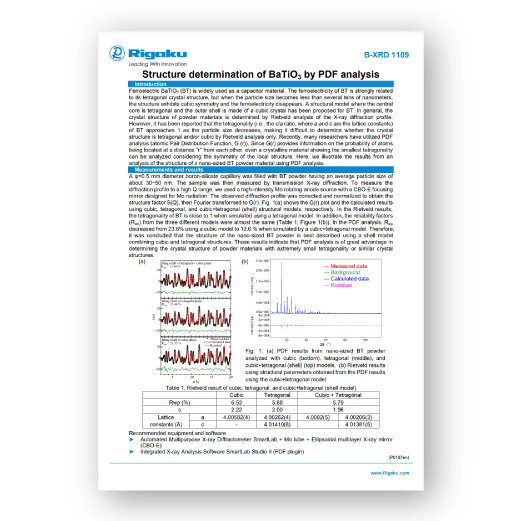

Structure determination of BaTiO3 by PDF analysis

This app note from Rigaku summarizes how XRD is used to measure the atomic Pair Distribution Function (PDF) of semiconductor materials.

-

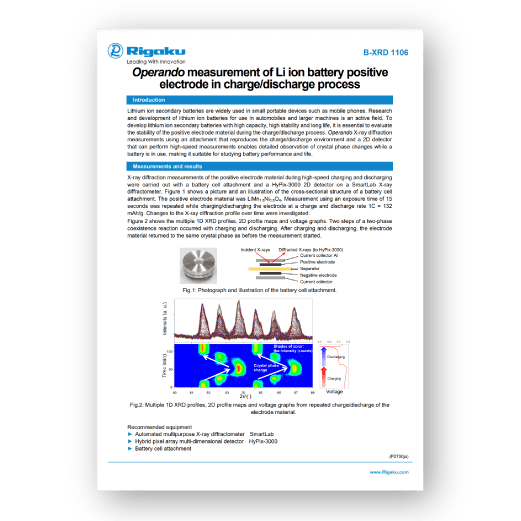

Operando measurement of Li ion battery positive electrode in charge/discharge process

Operando measurement of Li ion battery positive electrode in charge/discharge process Click below to download this Application Note Lithium ion secondary batteries are widely used in small portable devices such as mobile phones. Research and development of lithium ion batteries for use in automobiles and larger machines is an active field. To develop lithium ion…

-

Identification of the crystal form of the active pharmaceutical ingredient in a tablet

Experts at Rigaku summarize how to use their SmartLab XRD system to characterize the crystal form of an active pharmaceutical ingredient.

-

Measurement of microscopic regions using a high-speed 2-dimensional detector

Measurement of microscopic regions using a high-speed 2-dimensional detector Evaluation of microscopic regions of carbide tools Click below to download this Application Note Carbide tools used for cutting are provided with various types of coatings to improve durability. Previously, evaluation of the coating layer has been done using X-ray diffraction, but some users want to…

-

X-ray Diffraction Offcut Measurement

X-ray Diffraction Offcut Measurement ABSTRACT In this application note, Dr. Frazer summarizes the impact of offcut angle on thin film growth, and goes on to detail the process by which offcut angle is analyzed using X-ray Diffraction (XRD). Each step of this industry-standard procedure is demonstrated on a NIST standard Al2O3Â sample wafer, and the computation…

-

Covalent Metrology Overview

Covalent Metrology Overview Datasheet Click below to download the Datasheet Covalent Metrology delivers quality data and expert analysis for advanced materials and device innovation. Our unique combination of cutting-edge analytical instruments and world-class team of scientists enables us to provide our clients with actionable, accurate and affordable data and insights to accelerate the development ofproduct…

-

Black and green: catalyst and membranes for fuel cells

Black and green: catalyst and membranes for fuel cells The role of particle size, zeta potential and surface zeta potential in the development and quality control of catalyst and ion exchange membranes for fuel cells. Click below to download this Application Note Excerpted from the Text: In this application report we will focus on catalytic…

-

Particle size and zeta potential of electrode materials: better characterization, better performance

Particle size and zeta potential of electrode materials: better characterization, better performance Safe and long-lasting batteries optimized with particle characterization of electrode materials and possible additives Click below to download this Application Note Excerpted from the Text:Nowadays the power efficiency of many portable devices such as mobile phones, tablets or speakers is extremely related to…

-

AFM Polymer Surface Characterization

AFM Polymer Surface Characterization Using Tosca series atomic force microscopes to characterize polymer blends in terms of high-resolution morphology and polymer distribution. Click below to download this Application Note The surface properties of polymeric materials are central to their behavior in formulation and manufacturing processes, as well as in their target applications. Tosca AFM is…

-

Full Atomic Force Microscopy Investigation of a Polymer Thin Film with Tosca series AFMs

Full Atomic Force Microscopy Investigation of a Polymer Thin Film with Tosca series AFMs Due to its unique design, Tosca AFM offers the exceptional possibility to investigate mechanical, electrical and magnetic sample properties on the same location with a single hardware set-up. Click below to download this Application Note Excerpted from the Text:In addition to…

-

Analysis of laboratory nitrile gloves: From pores to the surface

Analysis of laboratory nitrile gloves: From pores to the surface Here we describe an approach where the use of multiple techniques has enabled a complete physical characterization of the rubber glove material. Click below to download this Application Note Excerpted from the Text:In this study, we demonstrate a new, holistic way to characterize surfaces of…

-

Applications of indentation on polymers

Applications of indentation on polymers Typical applications of nanoindentation for characterization of viscoelastic, creep and temperature dependent properties of polymers. Click below to download this Application Note This application report presents several applications of nanoindentation for characterization of polymers. The main part is dedicated to characterization of viscoelastic properties of polymers but the nanoindentation stress-strain…

-

Droplet Size Matters: Bioavailability of CBD Emulsions

Droplet Size Matters: Bioavailability of CBD Emulsions The Litesizer 500 enables precise and straightforward dynamic light scattering (DLS) and electrophoretic light scattering (ELS) measurements to determine the particle size distribution and zeta potential of CBD emulsions. Click below to download this Application Note Excerpted from the Text: Absorption, improved bioavailability in general and predictable dosing…

-

Surface Area Determination of Battery Cathode and Anode Materials

Surface Area Determination of Battery Cathode and Anode Materials In order to optimize their design efforts, battery developers rely on accurate characterization of the physical properties of the components used in their designs. Click below to download this Application Note Excerpted from the Text: Surface area is a critical property for battery components including anodes,…

-

Surface Spectroscopic Techniques for Chemical Analysis

Surface Spectroscopic Techniques for Chemical Analysis Click below to download this eBook Excerpt from the Introduction: For most materials, surfaces are the point of interaction with the world, and, as scientists and engineers, understanding the physical and chemical properties of surfaces can give light to many of the issues with, and opportunities to improve, modern materials.…

-

Covalent Metrology Acquires Riga Analytical Lab

Covalent Metrology Acquires Riga Analytical Lab Long-time industry expert’s team and resources to join Covalent’s rapidly growing operation, offering one of the broadest service portfolios in North America to more than 500 customers combined Share this News on Social Media: September 1, 2020 – Sunnyvale, CA. Covalent Metrology, a leading provider of metrology and analytical services to advanced…