Spectral Ellipsometry (SE)

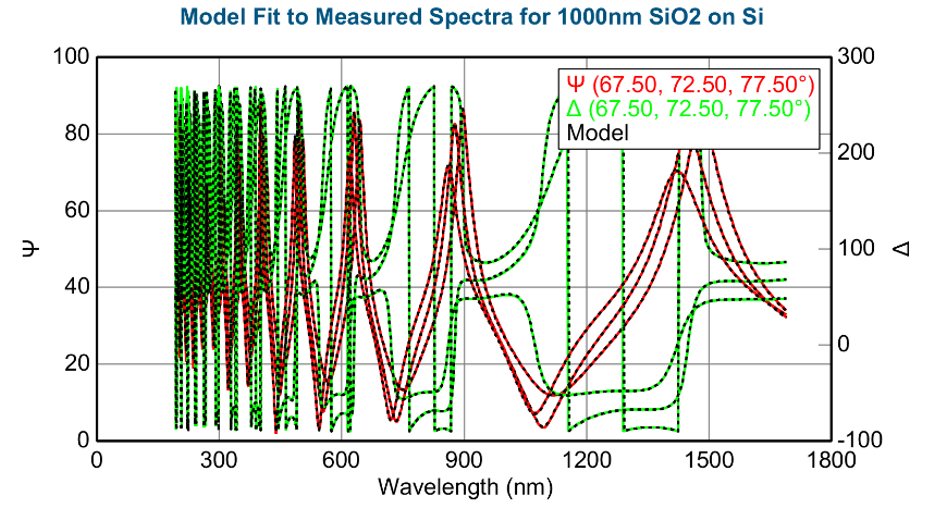

Spectral ellipsometry (SE) – also called “spectroscopic ellipsometry” – is a non-contact, non-destructive optical characterization technique that can be used to assay numerous physical, optical, and topographical properties simultaneously and indirectly.

With the development of appropriate analysis models, examples of material properties that can be measured by ellipsometry include:

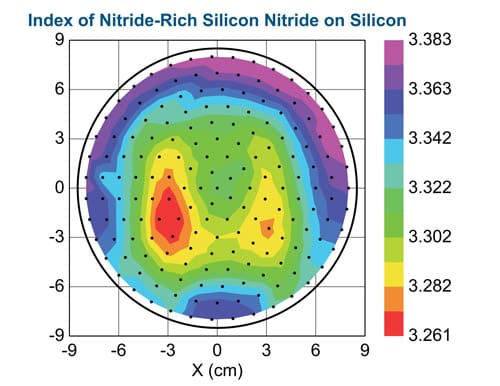

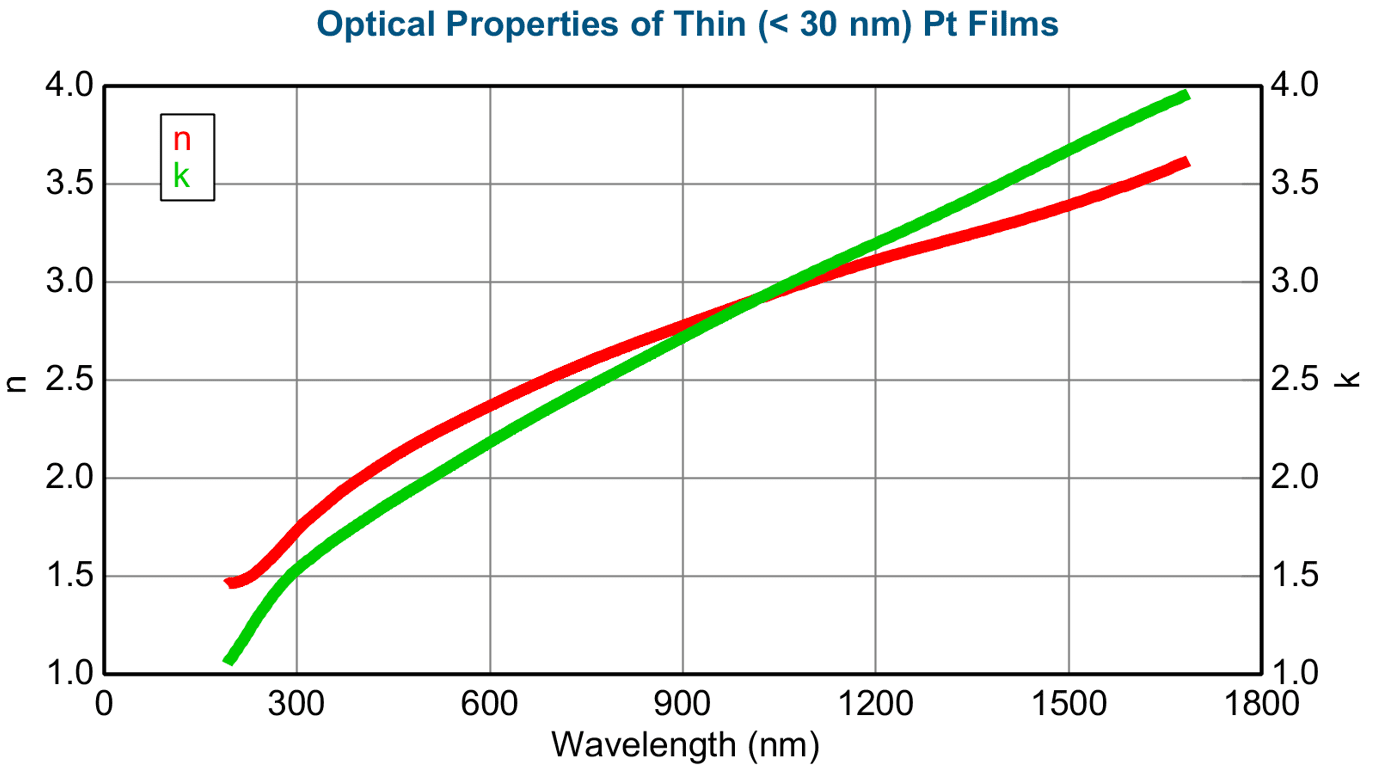

- Layer thickness and optical properties (n, k)

- Surface and interface properties

- Film density and porosity

- Material quality and homogeneity

- Layer composition

- Birefringence

- Bandgap energy in semiconductors

- Depth gradients

- Monolayer coverage

Strengths

- Data collection is generally quick and straightforward

- Precise and reproducible

- Very sensitive to ultra-thin films (single angstroms thick)

Limitations

- Measured region on the sample must be smooth and flat

- Complex modeling required to access most indirect properties – often requires extensive expertise to avoid analytical pitfalls

- Analysis of multi-layered samples sometimes requires fabrication of intermediate test samples with fewer layers to uniquely determine the properties of all layers present