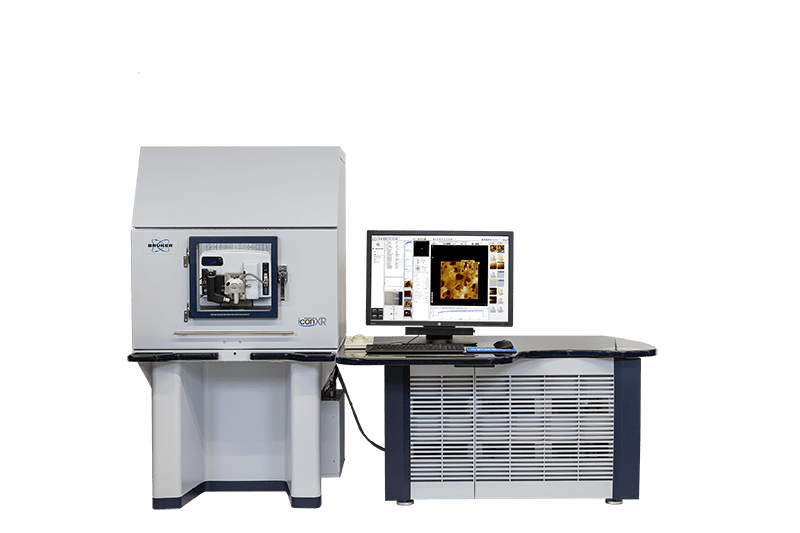

Atomic Force Microscopy (AFM)

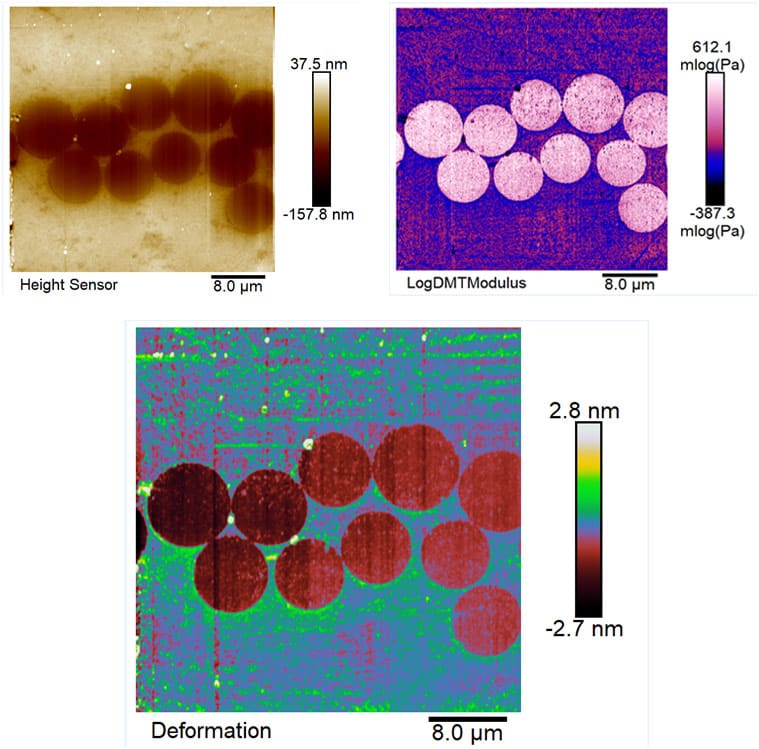

Atomic Force Microscopy (AFM) measures surface topography of materials with sub-nm vertical resolution. The technique delivers fast data, with simple scans requiring only a few minutes to complete.

Strengths

- Best height resolution among surface topography techniques

- High lateral resolution with specialized cantilever tips

- Rapid measurement: possible to capture images within 10 min

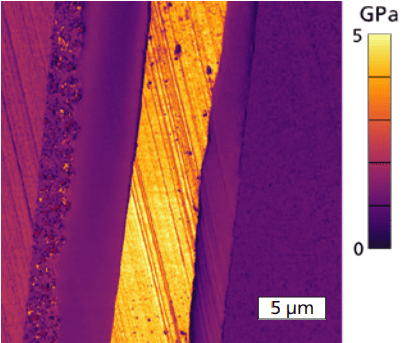

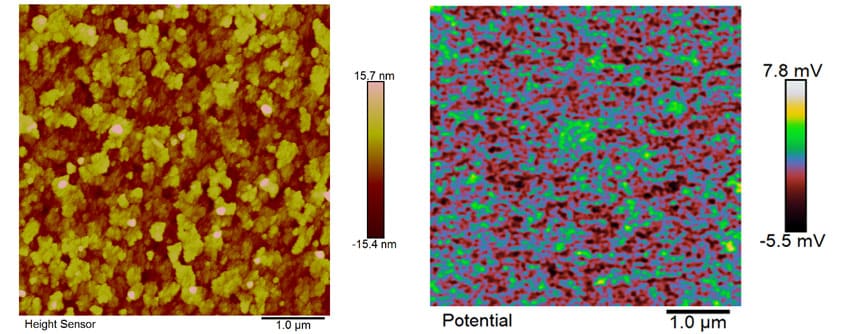

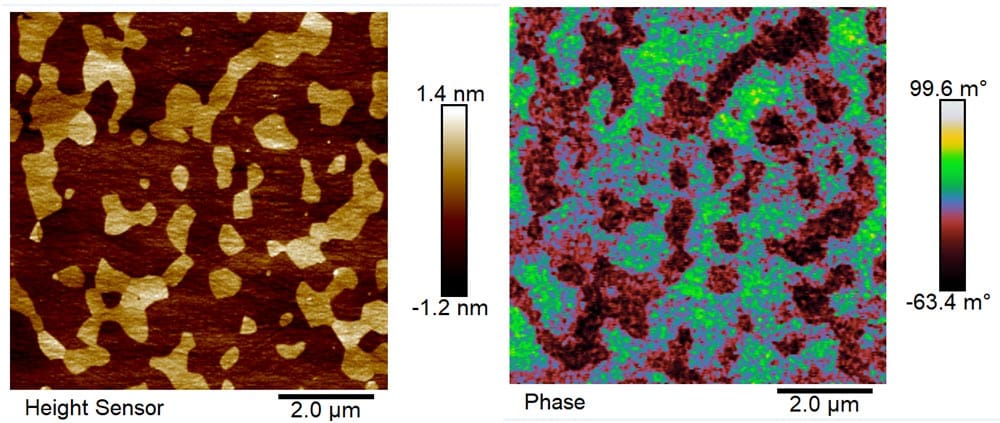

- Alternative force probes (including: electric, magnetic, piezoelectric, etc) accommodate advanced analytical modes

Limitations

- Limited field of view. Maximum scan size is 100 µm x 100 µm

- Roughness must be less than 10 microns

- Size, shape, and cleanliness of the tip may obscure the results