Understand Multilayer Thin Films on a New Level

Multilayer thin film devices are a cornerstone of modern photonics enabling precise light manipulation across many applications like laser optics, displays, and telecommunications. High performance devices and innovation in this field require high quality films controlled thanks to characterization of key properties such as smoothness, uniformity and optical performance.

Covalent’s Silicon Valley lab is equipped to offer comprehensive characterization of multilayer thin film stacks.

- Elemental composition of the films making up the stack

- Composition gradients

- Thickness of each layer of the stack

- Refractive index of each layer of the stack

- Mapping of composition, thickness, optical properties across 300mm

- Surface roughness measurement

- Roughness of interfaces between layers

- Detection of contaminants down to ppms, ppbs

- Detection of voids and delamination

- Scratch test, adhesion test

- Mapping and High Resolution Electron Microscopy imaging with EDS elemental analysis

Advanced Modeling

Covalent provides advanced optical modeling solutions that empower teams to optimize new designs by accurately predicting how changes in layer composition and thickness will impact optical performance.

Common Thin Film Applications

Antireflective (AR) and High-Reflectivity (HR) Coatings

Bandpass Filters

- Telecommunications

- Fluorescence microscopy

- Spectroscopy

Dichroic Filters

- Projection systems, cameras, lighting

Sensors

Laser Optics

- Telecommunications

- Fluorescence microscopy

- Spectroscopy

Waveguides and Integrated Photonics

- Photonic integrated circuits (PICs), such as modulators and wavelength multiplexers/demultiplexers

Display Technology

- Liquid crystal displays (LCDs)

- Organic light-emitting diodes (OLEDs)

- Augmented reality (AR)

Analysis Example: Multilayer Anti-reflection

Coating for Camera Lens

Challenge

Determine structure, optical properties, and anti-reflection (AR) performance without any starting knowledge of an AR coating

Approach

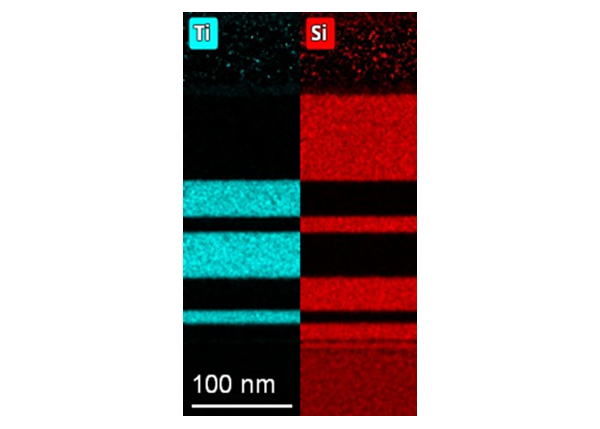

Cross Sectional EDS

Material identification, layer configuration, and approximate thicknesses.

EDS maps of stack cross-section used to determine composition and thickness of stack layers.

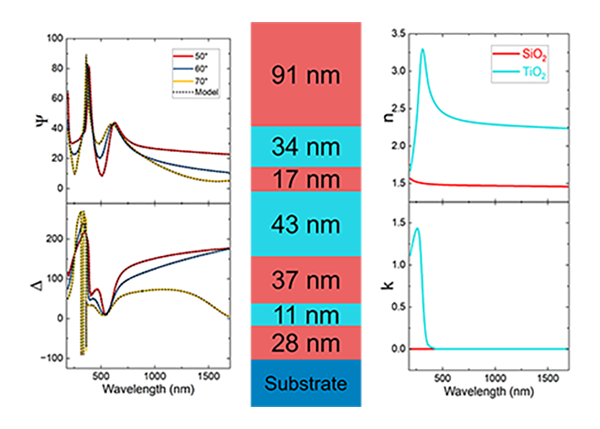

Spectroscopic Ellipsometry

Optical model development, precise layer thickness measurement, measurement of optical property spectra for each layer.

Spectroscopic ellipsometry combined with advanced optical modeling yield stack layers thicknesses, composition and optical properties (n,k).

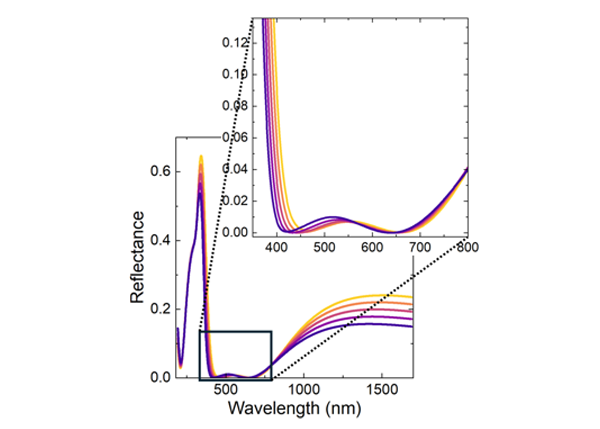

Optical Device Simulation

Simulation of AR coating performance, and design optimization.

Advanced modeling also allows to simulate variations in stack design and guide efforts to optimize device performance.

Results

Starting with zero knowledge of the coating and substrate, cross sectional EDS combined with spectroscopic ellipsometry produced data that Covalent experts used to create an accurate optical model of the device. Advanced simulation was then successfully used to recommend changes in design to achieve a better performing AR coating.