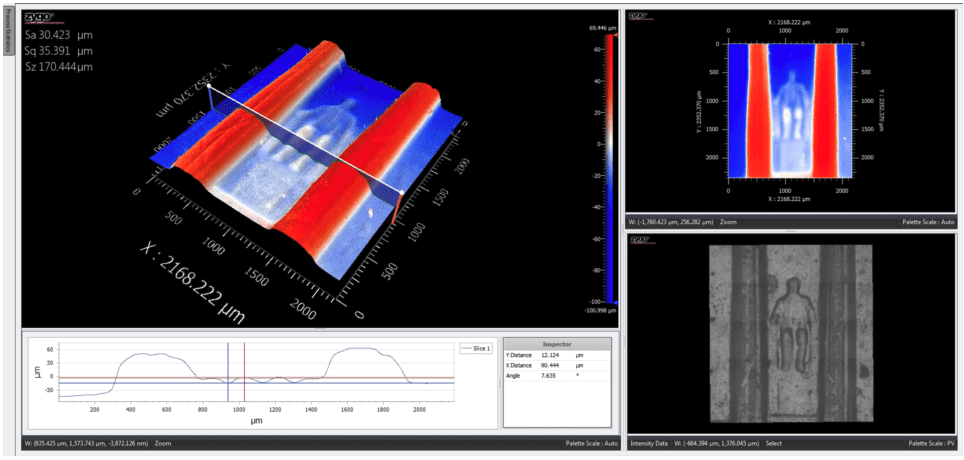

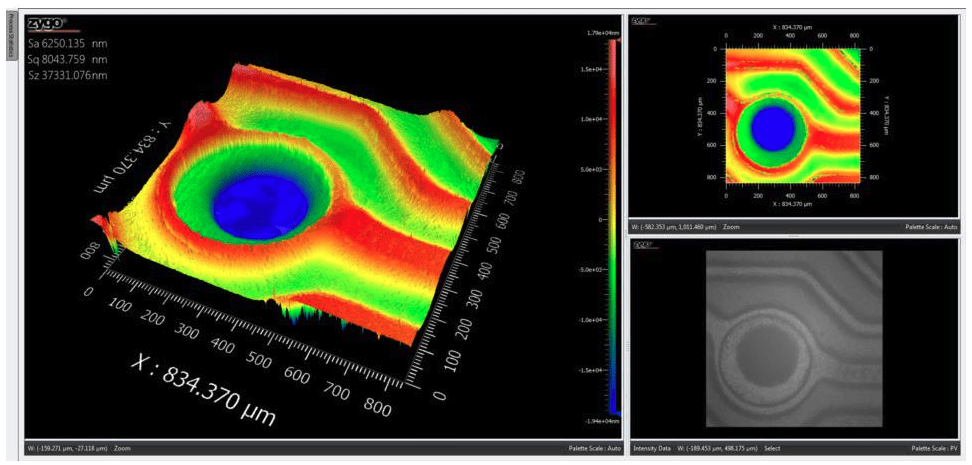

White Light Interferometry (WLI)

White light interferometry (WLI) is a non-destructive, non-contact, optical surface topography measurement that uses coherence scanning interferometry to generate 2D and 3D models of surface height.

Strengths

- Rapid results

- Superior lateral resolution (limit is ~160 nm) as compared to chromatic confocal, Laser Confocal and Wide Area Patterned Light Mapping

- Nondestructive measurement

- High vertical resolution: ~1 nm

Limitations

- Steep cut-offs and sharp topography angles impair WLI measurement accuracy around these features

- Interpretation of fringe changes can be difficult in certain types of samples