Gas Pycnometry (Pycnometry)

Gas Pycnometry is one of the most widely used techniques for analyzing the true and skeletal density of any solid (even ones which are porous, granular, and irregularly shaped!). It provides fast, high-accuracy volume measurements that can be used to calculate density and porosity and can be adapted to analyze the purity, quality, volatile organic content, and stability of certain materials.

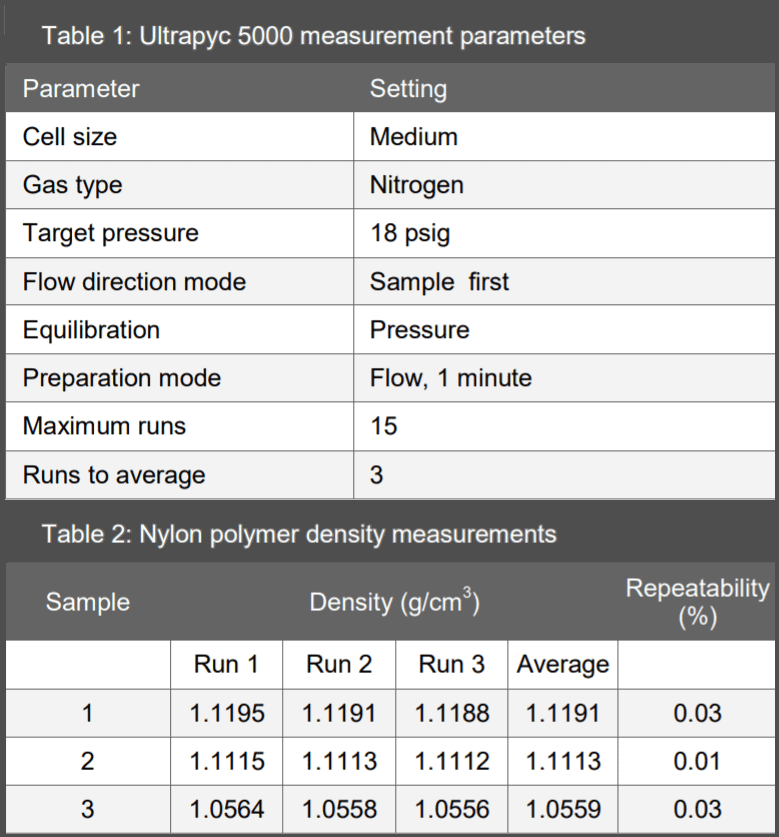

Covalent uses an industry-leading Ultrapyc 5000 Gas Pycnometer from Anton Paar for true density analysis. This tool achieves best-in-class accuracy across ranged sample types, including coatings, polymer foams, cement, mining, pharmaceuticals, ceramics, catalysts, metallurgy, and more.

Strengths

- Unmatched volumetric measurement accuracy

- Excellent reproducibility and reliability

- Flexible analytical modes for wide array of sample types

- Raw measurement can be used to calculate numerous material properties

Limitations

- Density must be calculated using separately measured sample mass

- Porosity does not include closed pores (e.g. pores which are not permeable through solid surface)