In-situ heating Transmission Electron Microscopy (In-situ heating TEM)

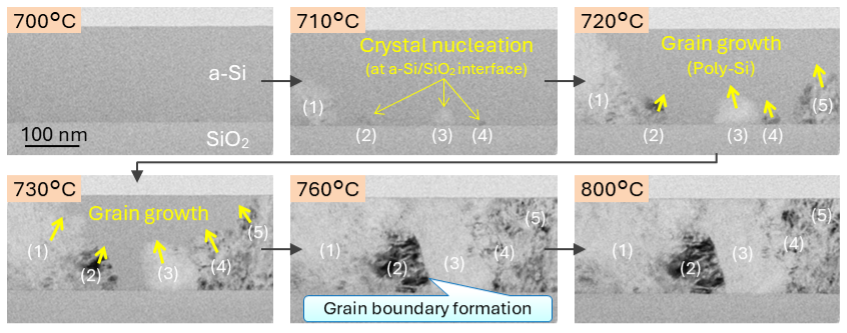

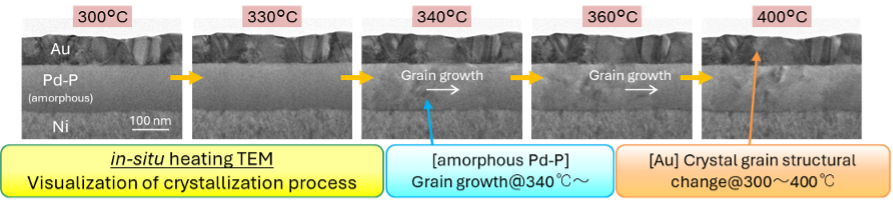

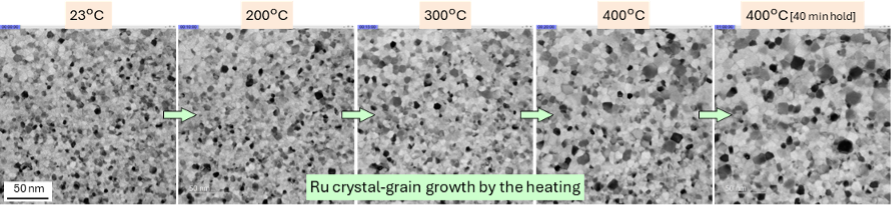

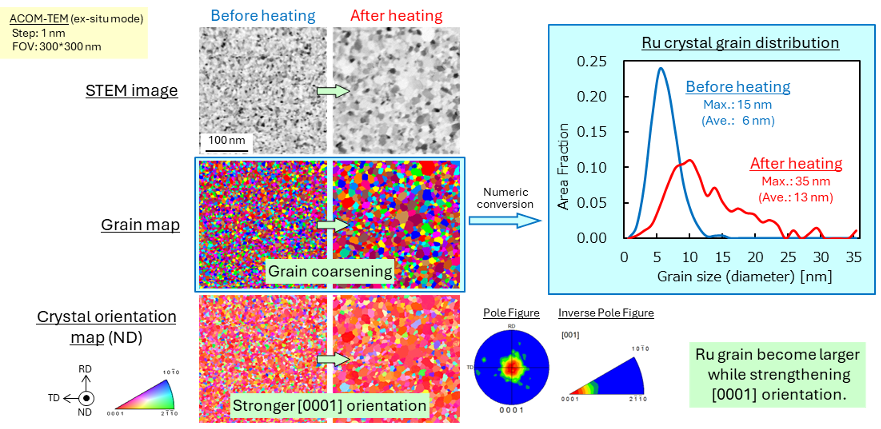

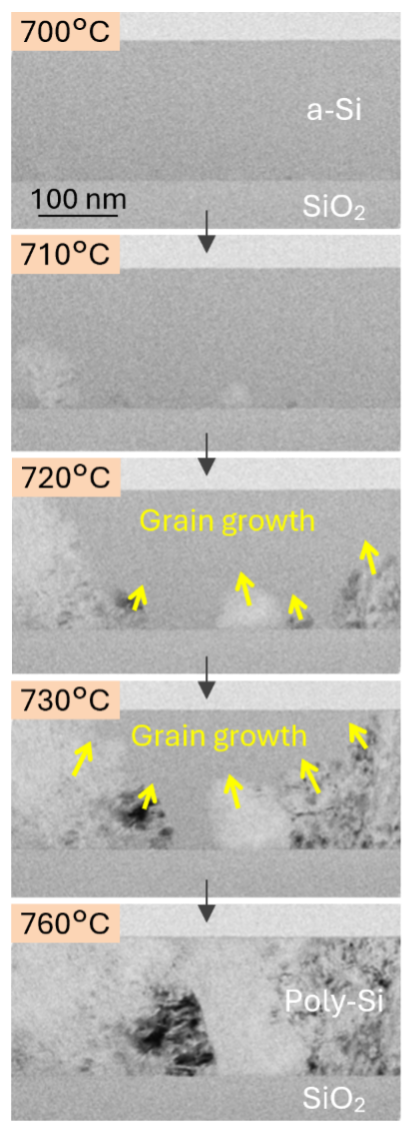

In-situ heating TEM technique make it possible to observe the thermal behavior of materials with nano-meter-level during heat treatment.

Semiconductors (including bonding interface), Metals, Nanomaterials, etc.

Strengths

- Observation at multiple temperatures in a single sample

- Visualization of thermal behavior at the same position: starting point of change (When? Where?), and Process of change (How?)

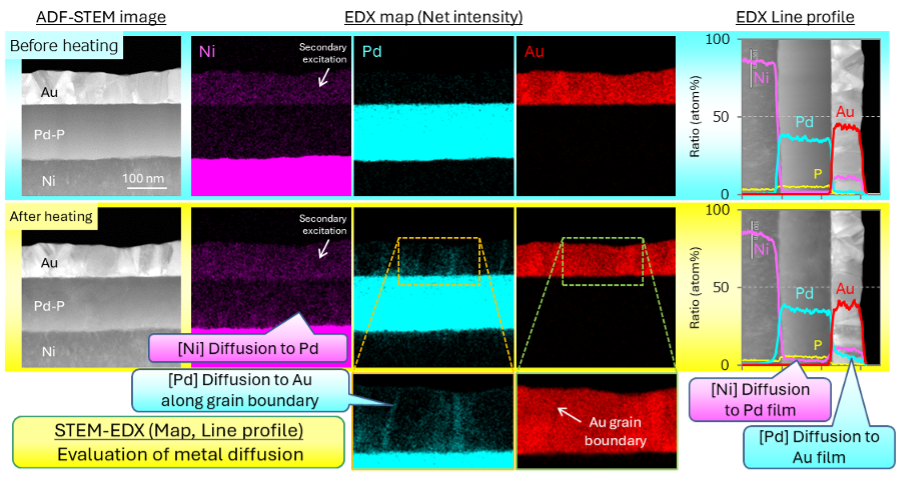

- Combination with other (S)TEM-based methods from the same field of view as in-situ heating TEM:

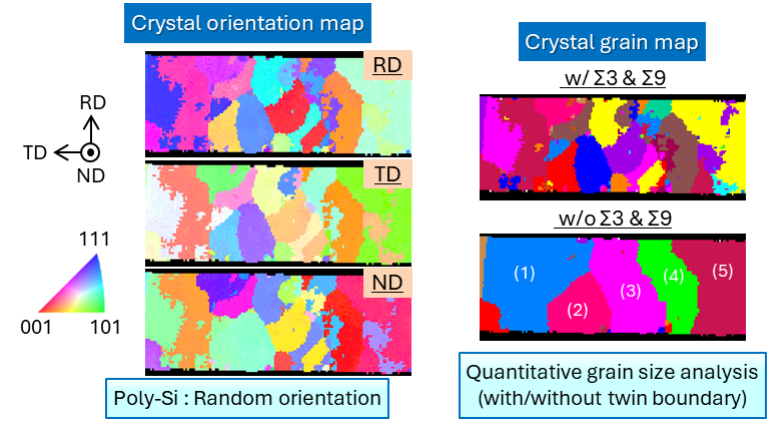

- Crystal orientation analysis, Grain size analysis: ACOM (Automated Crystal Orientation Mapping)-TEM

- Elemental composition analysis (elemental diffusion): EDX (Energy Dispersive X-ray spectroscopy) / EELS (Electron Energy Loss Spectroscopy)

Limitations

- Atmosphere: in vacuum (not gas, not under pressure)

- Evaluation sample: thin film (not bulk)

- Effects of electron irradiation (e.g., reaction acceleration): it can be reduced by optimizing the electron beam irradiation conditions