Micro X-ray Computed Tomography (Micro-CT)

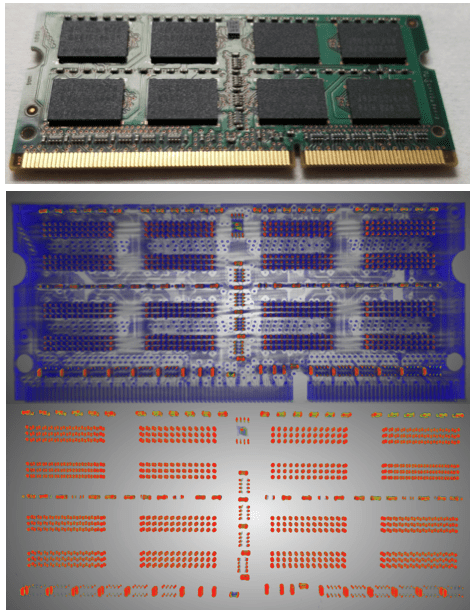

X-ray computed tomography (often referred to as Micro-CT due to its spatial resolution) is a non-contact, non-destructive 2D and 3D imaging technique used to capture morphology and topography at the micron scale of the exterior and interior of the sample.

Covalent uses a best-in-class benchtop Micro-CT instrument, the CT Lab HX130. Covalent’s tool is the only HX130 system available for service in North America outside of Rigaku Corporation.

Strengths

- High spatial resolution of 2D images and subsequent 3D models

- Easily accesses interior structures and buried topographies in both industrial and biological samples

- Minimal to no sample preparation is required

- Nondestructive analysis

Limitations

- Resolution depends on sample size, shape and composition

- Post-processing can take significantly longer than measurement times