Taber testing applies linear or rotary forces to the surface of a sample, with variable pressure / rotation speeds, respectively. Abrasion damage on the sample is analyzed to determine the specimen’s wear resistance.

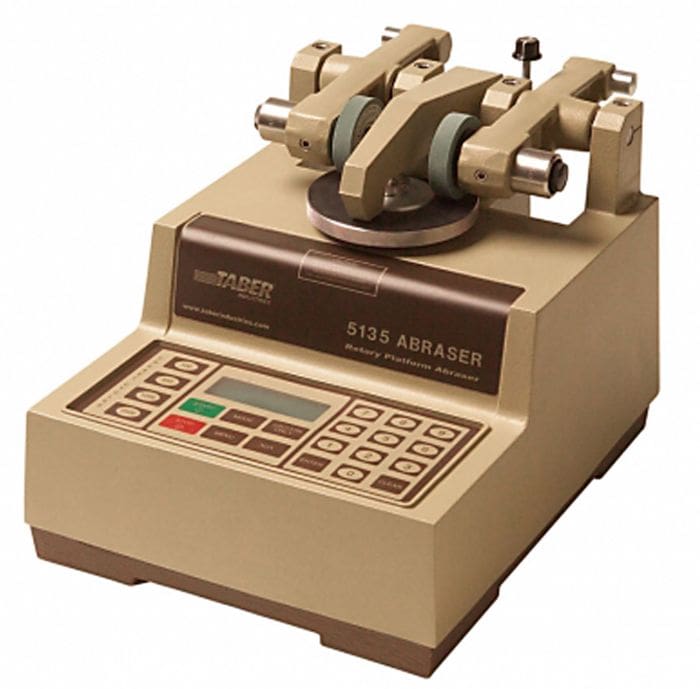

In a standard “taber test” of wear behavior, the material of interest is mounted on a turntable platform.

For circular taber abrasion, two abrading wheels are placed in contact with the surface, with a set applied pressure and rotary speed. These wheels induce friction / shear damage in the sample due to its sliding contact with the abrading wheels as they spin and the turntable mount is rotated.

For linear taber abrasion, a counterbalanced arm with precise applied pressure is dragged across the sample surface as the specimen platform is laterally moved under it. As in the rotary case, the scraping and sliding of the sample in contact with the arm produces damage marks.

At the conclusion of either abrading process, the sample is subsequently profiled using optical or scanning-probe imaging techniques to evaluate the extent of wear.