The bulk density of a powder sample depends upon its preparation, as well as subsequent treatments, processing, and storage. Handling granular materials causes their particulates to rearrange and pack together due to cohesion and shape effects, and this forms the basis of tap density analysis. The tapped density of a powder provides a quantitative metric of its compressibility and maximum packing efficiency.

Together, these properties are crucial to controlling quality in raw powders used in numerous production materials, such as: cement, dolomite, and bitumen in construction work as well as in pressed pharmaceutical pills and capsules.

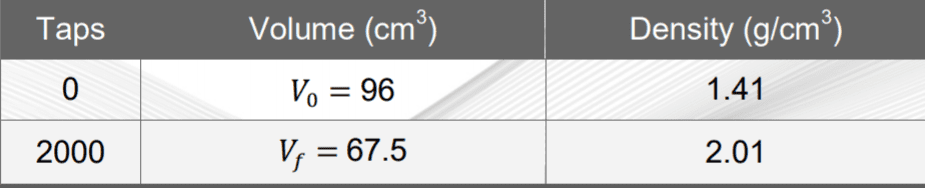

To make a tap density measurement on a sample, its mass must first be measured using a high-sensitivity scale. Once the mass is known, the sample can be loaded into a graduated cylinder mounted on the analyzer (sometimes called a “tap volumeter”). The initial bulk density is calculated using the reported volume after the powder settles. Then, the cylinder is mechanically tapped many times to redistribute the particulates until no further volume change is detected. To maximize volume accuracy, the cylinder is automatically rotated to promote a flat powder interface.

The tap density is computed using the measured volume after the volume stabilizes. It is almost always lower than the initial bulk density.