Total Reflection X-ray Fluorescence (TXRF)

TXRF is a surface sensitive elemental analysis technique used to determine the concentration of trace metal contamination on wafer surfaces.

Strengths

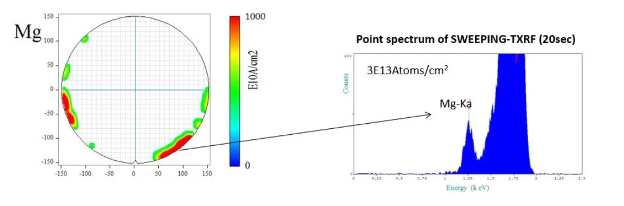

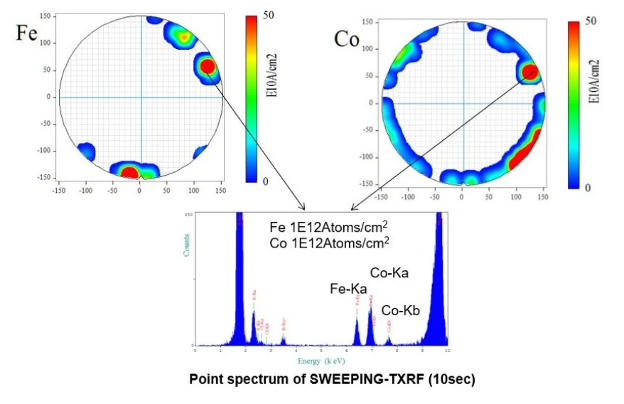

- Ultra-trace sensitivity (down to 1E10 atoms/cm²)

- Non-destructive wafer surface analysis

- Minimal sample preparation

- High throughput with automated wafer handling

- Excellent repeatability and reproducibility

- Wide elemental range (Na to U)

- Contamination mapping and site-specific measurement

Limitations

- Primarily surface-sensitive; not for bulk analysis

- Requires flat, reflective wafer surfaces

- Interference from thick films or rough surfaces

- Limited lateral resolution compared to microscopy techniques