Wavelength Dispersive X-ray Fluorescence Spectroscopy (WDXRF)

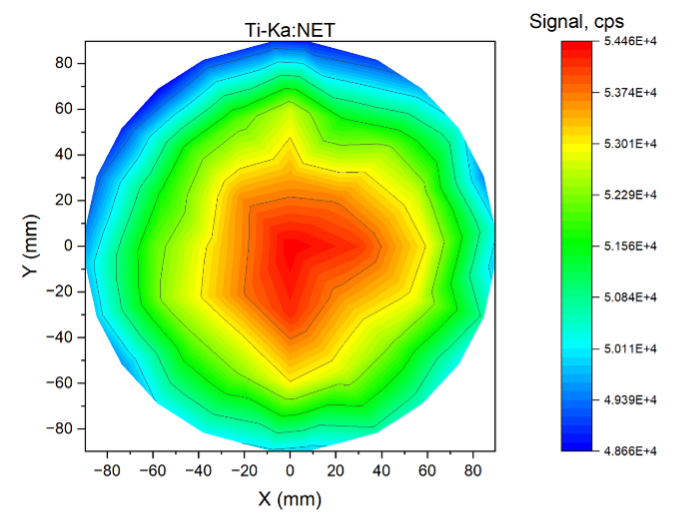

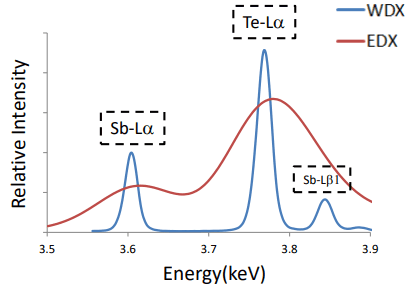

Wavelength Dispersive X-ray Fluorescence (WDXRF) provides highly precise, non-destructive elemental analysis, ideal for quality control in semiconductor manufacturing and other applications. Customers choose WDXRF when they need highly accurate thin film composition, thickness, and contamination analysis across wafers or materials.

Application areas:

- Semiconductor manufacturing (front-end and back-end)

- Compound semiconductors (GaN, SiC, InP, etc.)

- Data storage media (hard drives, magnetic films)

- Solar/Photovoltaics

- Display technologies (OLED, LCD)

- Advanced packaging and interconnects

- Research and development labs

Strengths

- High accuracy and precision for thin films and multilayers

- Non-destructive analysis

- Excellent performance for light and heavy elements

- Wide dynamic range: ppm to 100%

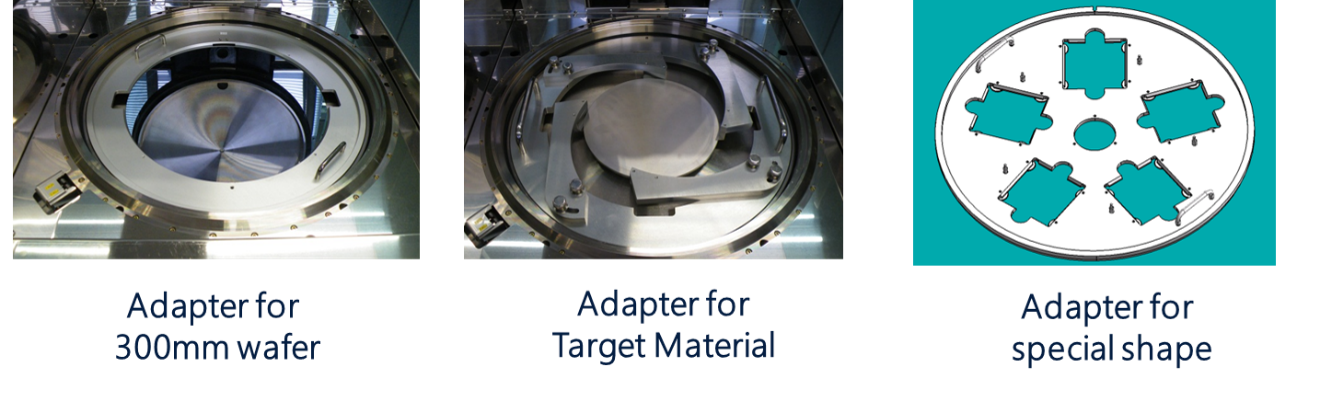

- Automated, production-ready platform

- Minimal sample prep

- Long-term stability for inline/QA monitoring

- Quantitative analysis without standards (Fundamental Parameters method)

Limitations

- Lower throughput compared to techniques like TXRF for quick screening

- Requires flat and relatively uniform samples

- Vacuum or helium atmosphere may not be compatible with volatile samples

- Typically limited to surface and near-surface layer analysis

- Larger footprint instrument compared to handheld or benchtop XRF