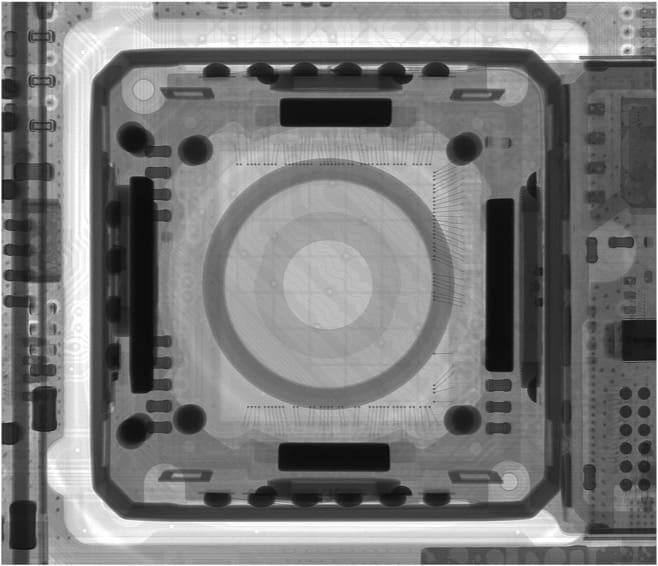

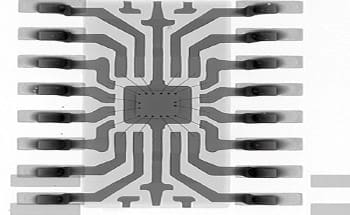

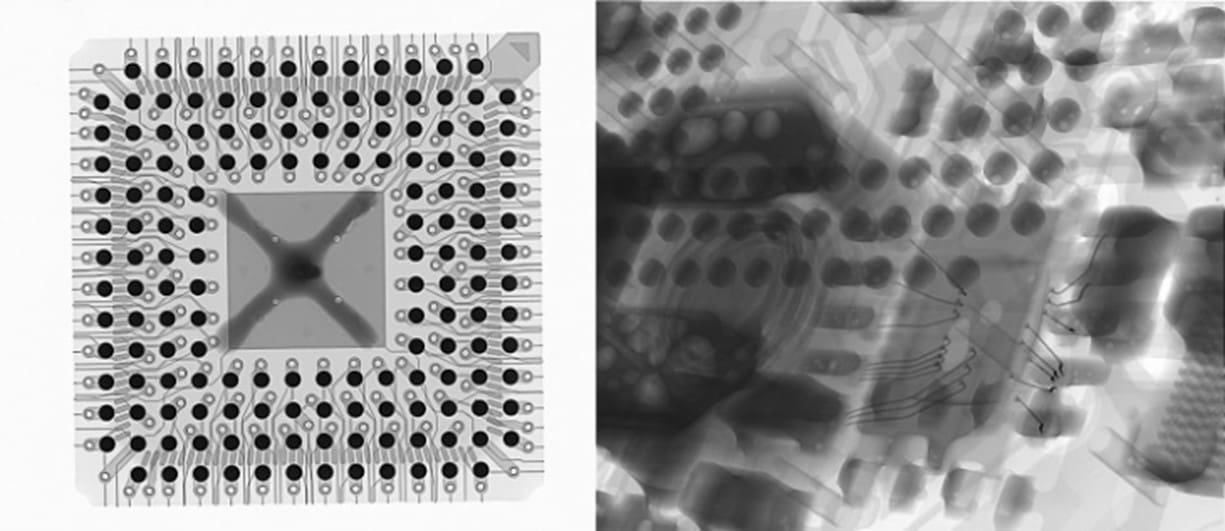

X-ray inspection systems use a point source to emit high-energy X-rays which pass through your sample. The transmitted X-ray photons are projected onto a detector, resulting in an image whose contrast is determined by the densities and thicknesses of the sample materials. Denser and thicker materials absorb more X-rays and are subsequently represented as darker regions in the final image. A high-pixel density digital detector enables an operator to generate these images in real time. In conjunction with sophisticated analytical software, modern detectors have enhanced the accuracy, useability, and throughput of modern x-ray imaging systems.

The source voltage can be manipulated to alter the spectral range of the emitted X-rays. Higher energy X-rays have a lower attenuation coefficient, meaning more photons will pass through a given feature. By adjusting source voltage and other parameters, such as exposure time, the system can be fine-tuned to produce optimal images on a variety of samples.

X-ray inspection is frequently employed for failure analyses or quality control inspections on PCBAs, electrical components/ICs, BGA solder balls, welds, batteries, precision machined components, and surgical implants.