X-ray Photoelectron Spectroscopy (XPS)

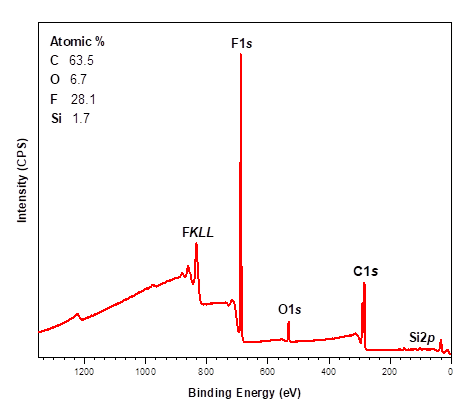

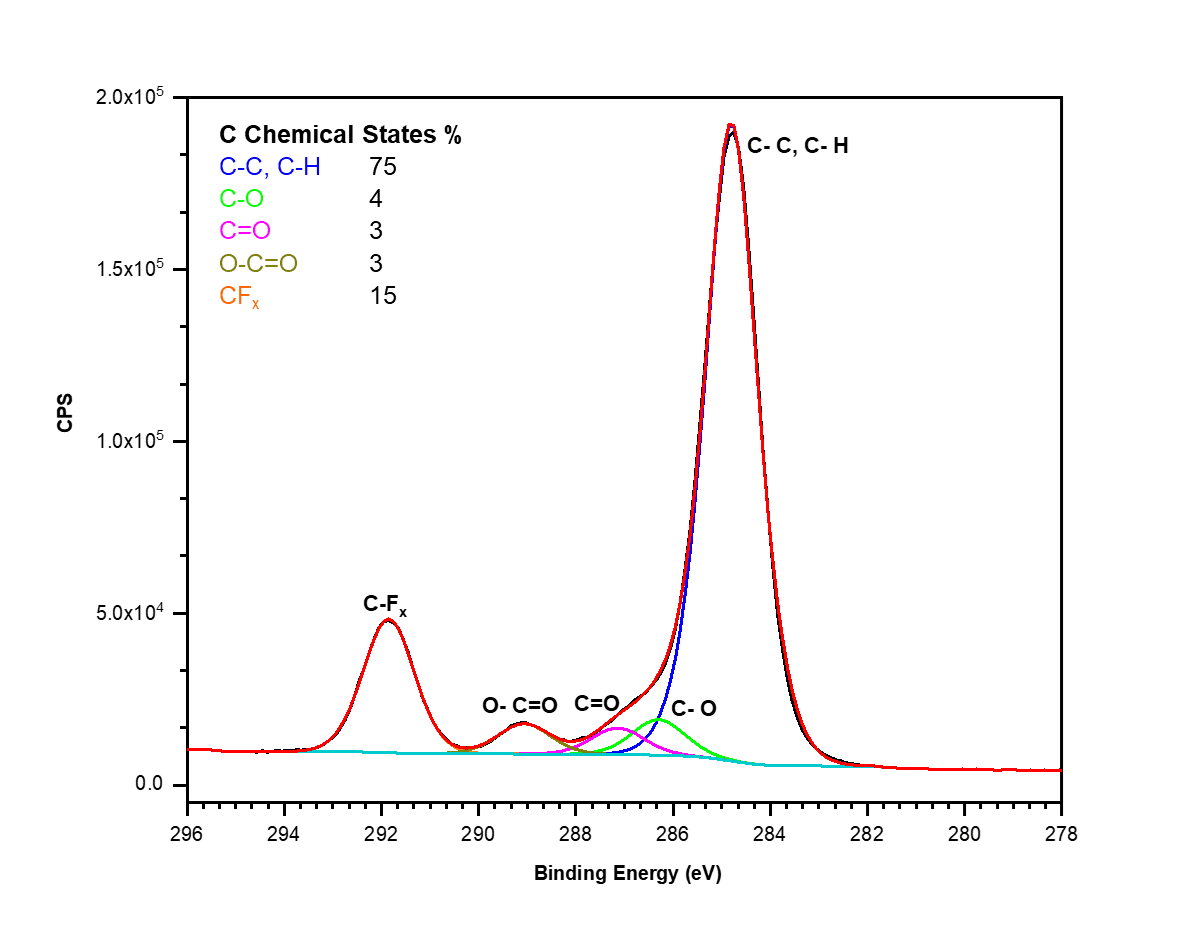

X-ray photoelectron spectroscopy (XPS) is a highly surface-specific chemical analytical technique used to probe the elemental composition and bonding states in the outermost 2-10 nm of a solid surface.

Strengths

- Quick and easy sample preparation

- Rapid data acquisition

- Accurate quantitative elemental composition in the near-surface region (2-10 nm)

- Charge neutralization is possible for non-conducting materials

Limitations

- Lateral resolution limited to about 10 microns

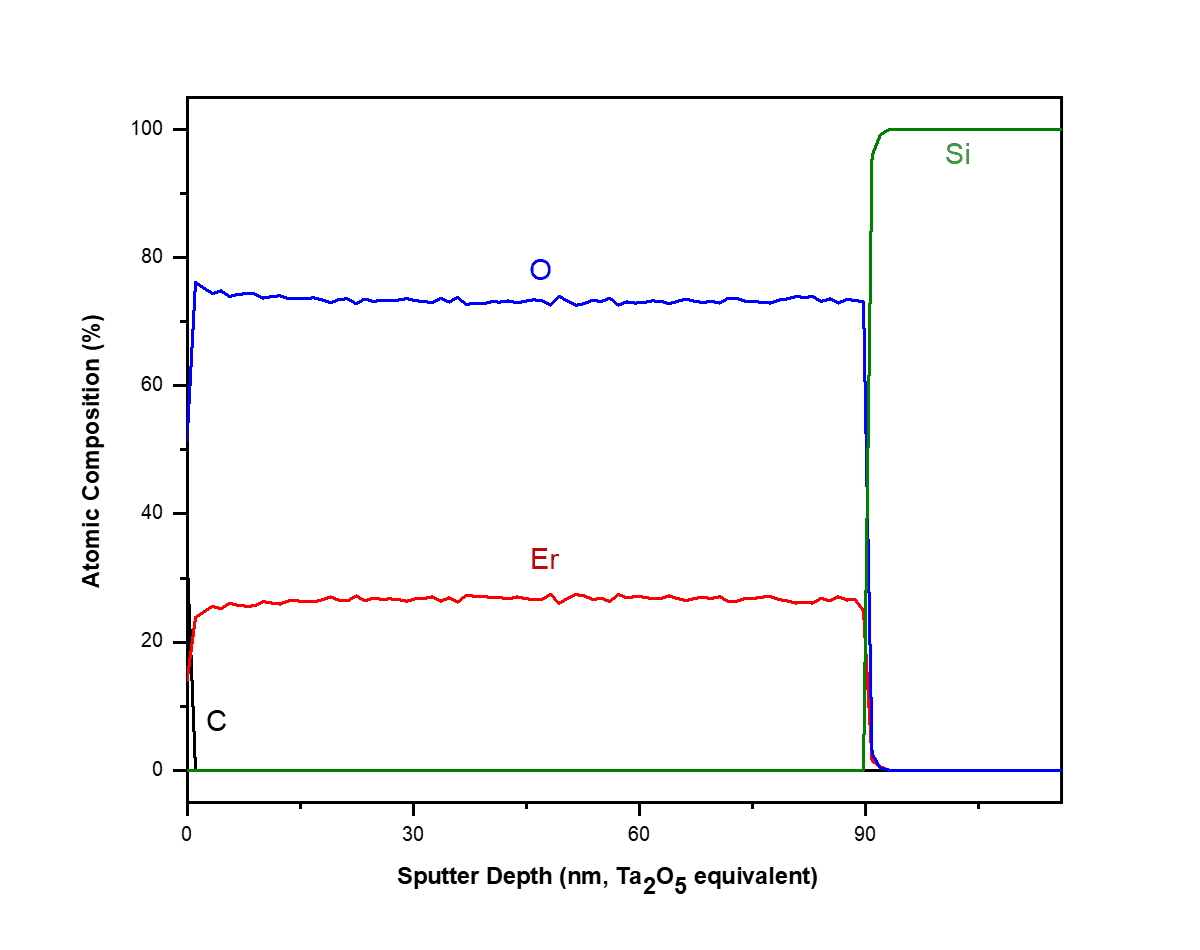

- Sputter depth profiling to assay chemical changes with depth can lead to artifacts and sample damage

- Bonding information cannot always be determined