Porosimetry

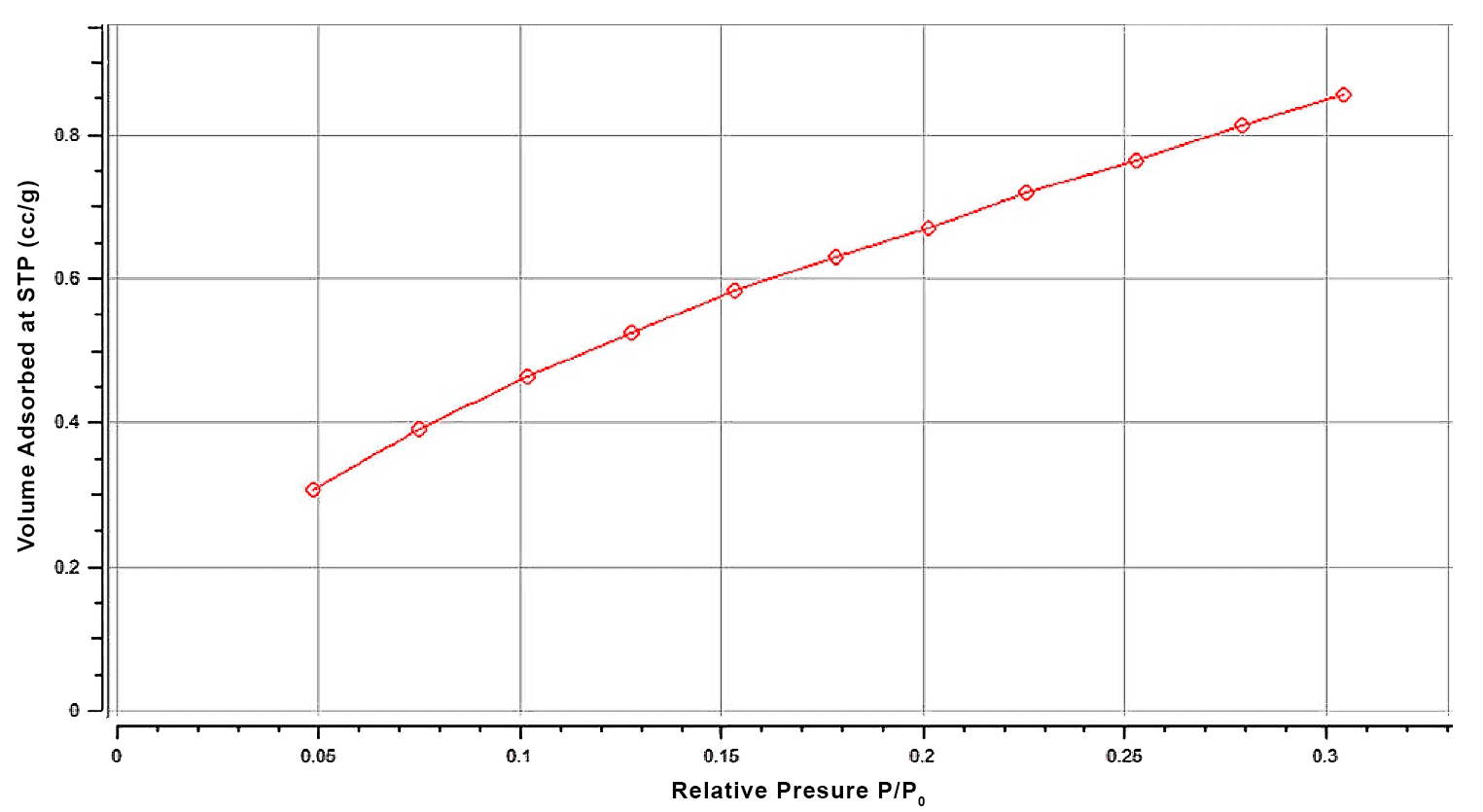

Porosimetry (also called “Gas Adsorption,” “Physisorption” Analysis, or “BET Analysis”) is a highly flexible and accurate technique for measuring specific surface area, pore sizes / size distribution, and overall porosity of solid samples as well as active metal area, dispersion, and crystallite size for materials with gas-reactive surfaces like catalysts. These can impact electrical, physical, and thermal properties and affect the overall performance of devices and systems.

See also:

Capillary Flow Porometry (or Porometry) is an alternative porosity measurement technique better suited for permeable samples.

Strengths

- Efficient characterization of solid sample surface area, porosity, pore size distribution, active metal area, dispersion and crystallite size

- Highly accurate, detailed, and reproducible

- Accommodates high-throughput analysis

- Automated sample preparation to maximize precision

Limitations

- Not optimized for large pore sizes (greater than 0.5 μm)