Surface Characterization Solutions for Biomaterial and Medical Applications

A Workshop on Solid Surface and Solid-Water Interface Analyses with Anton Paar

May 2, 2024, from 9:45 AM – 4:00 PM

at Covalent Metrology Lab in Sunnyvale, CA

Overview

In this workshop, we focus on the mechanical and chemical properties of material surfaces relevant to biomaterials and medical applications. The program comprises an introductory seminar to gain insights into the analytical methods for measuring zeta potential (surface charge), hardness, elasticity, and adhesion, followed by a practical session using the corresponding instruments and dedicated samples.

Read More: Zeta Potential

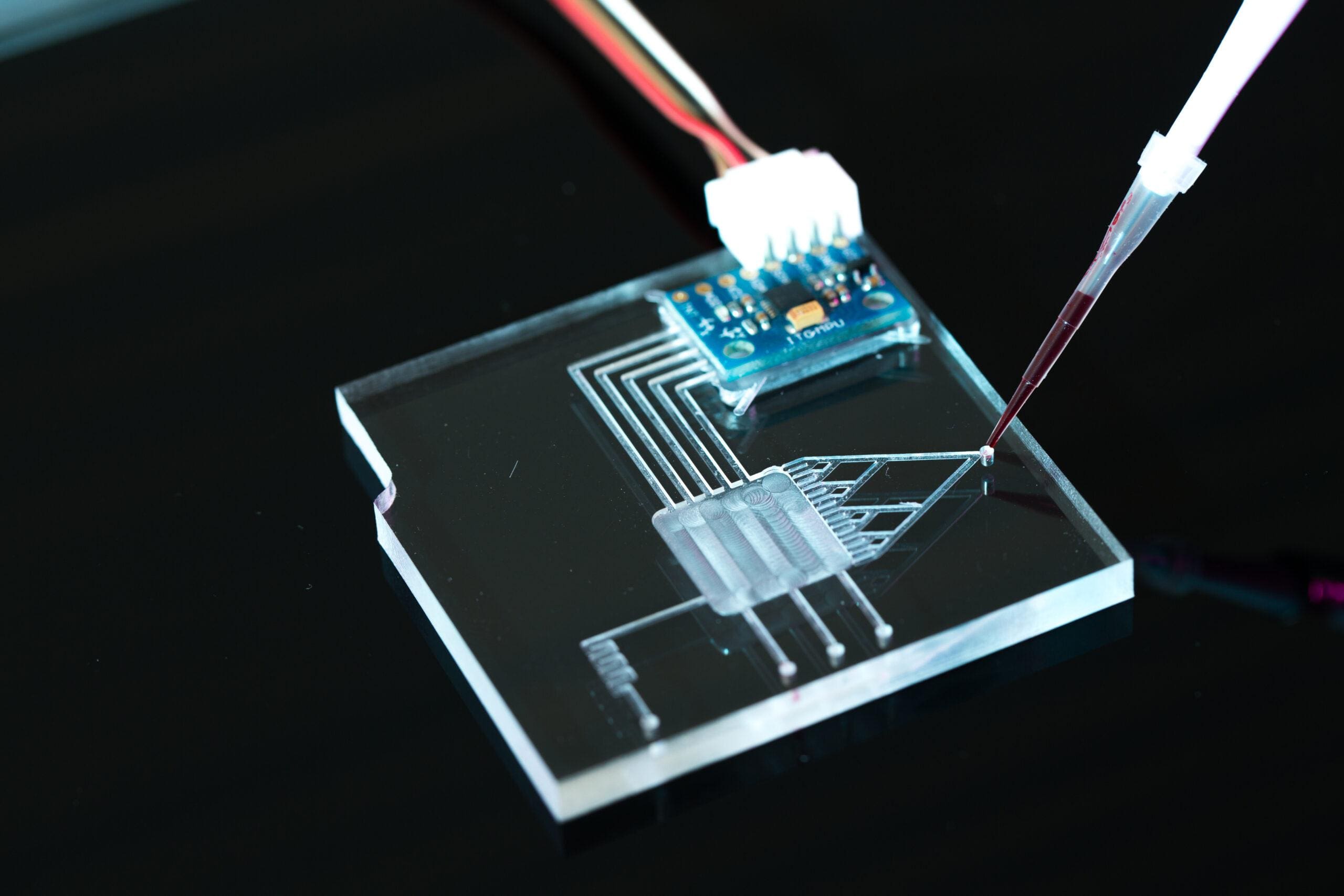

The zeta potential is a fundamental characteristic of the solid-water interface. It represents surface and interfacial charge. In spite of a common theoretical background, the analytical methods for the zeta potential analyses differ significantly for particle dispersions (by electrophoretic light scattering) and solid material surfaces (by streaming potential).

The analysis of the surface zeta potential serves versatile applications. In this workshop, we focus on case studies relevant for biomaterials and medical devices. We combine the analysis of equilibrated material-water interfaces with the dynamics of adsorption processes to elucidate protein interaction with material surfaces.

Read More: Nanoindentation

Nanoindentation is a surface characterization technique used for measuring the mechanical properties of materials such as hardness, modulus, viscoelasticity, creep, and fracture toughness. Nanoindentation, unlike conventional mechanical testing techniques, is particularly useful for characterizing the properties of complex materials such as composites, thin films and coatings, and soft materials such as hydrogels. In this workshop, we will focus on how nanoindentation can provide unique insights into the behavior and performance of natural or human-made biological materials by evaluating their mechanical properties.

Read More: Nano-scratch Testing

Scratch testing is another surface characterization technique used to evaluate the cohesive and adhesive properties of thin films to determine the failure points of the film-substrate system. Of particular significance to the biomedical industry is the adhesion of coatings to stents, prostheses, and biomedical implants to ensure the compatibility and safety of the medical devices when they are applied to the human body. In this workshop, we will focus on how scratch testing can be employed for cohesion and adhesion testing of biomedical devices. Tribology is the science of interacting surfaces in relative motion to study properties such as friction, wear, and lubrication. In this workshop, we will provide case studies that highlight how tribology can be used to understand friction and wear in hip and knee implants under real-life operating conditions.

Program

9:15 AM

Registration

9:45 AM

Welcome and Introductions

10:00 AM

Presentation 1: The complementarity of solid surface and liquid phase zeta potential: Focus on biomaterials and medical devices

Anton Paar Speaker: Thomas Luxbacher, PhD

10:45 AM

Presentation 2: Evaluating the mechanical properties, adhesion, and wear in biomaterials and biomedical devices using surface characterization techniques

Anton Paar Speaker: Parth Kotak, PhD

11:30 AM

Presentation 3: Complementary techniques for surface and interface characterization

Covalent Speaker: to be announced

12:00 PM

Catered Lunch Break

1:00 PM

Hands-on Demonstrations: Measurement of Nanoindentation, Nano scratch, and Zeta potential

Thomas Luxbacher, PhD, and Parth Kotak, PhD

4:00 PM

End of Workshop

Reserve Your Spot

About the Speakers

Thomas Luxbacher, PhD

Principal Scientist

Anton Paar GmbH, Graz, Austria

thomas.luxbacher@anton-paar.com

Thomas Luxbacher is the principal scientist for surface charge and zeta potential at Anton Paar. Prior to his present role, he was a product manager for surface zeta potential analyzers for more than 15 years. Before joining Anton Paar, Thomas gained experience in the semiconductor and automotive businesses. He received his MSc and PhD degrees in Physical Chemistry from Graz University of Technology.

Parth Kotak, PhD

Application Scientist

Anton Paar USA, Torrance, CA

parth.kotak@anton-paar.com

Dr. Parth Kotak works as an Application Scientist with a focus on Mechanical Surface Characterization at Anton Paar USA. He received his Ph.D. in Mechanical Engineering from the University of Iowa in 2023. His research activities focused on the mechanical characterization of soft elastomers and polymer fibers for soft robotics applications and evaluation of the mechanical properties of Transition metal dichalcogenides (TMDs) for energy storage devices and flexible electronics.